challboy728

Well-Known Member

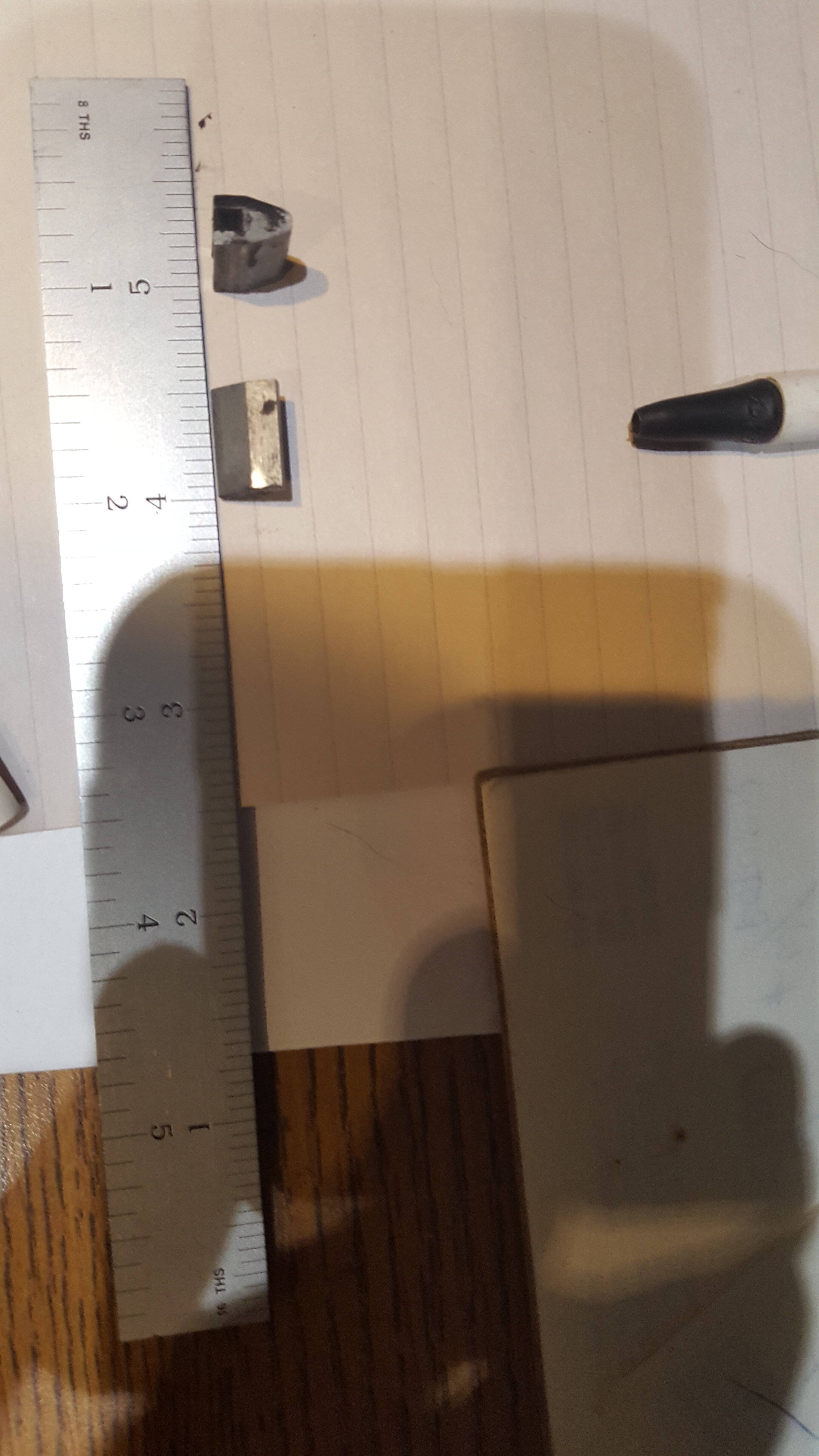

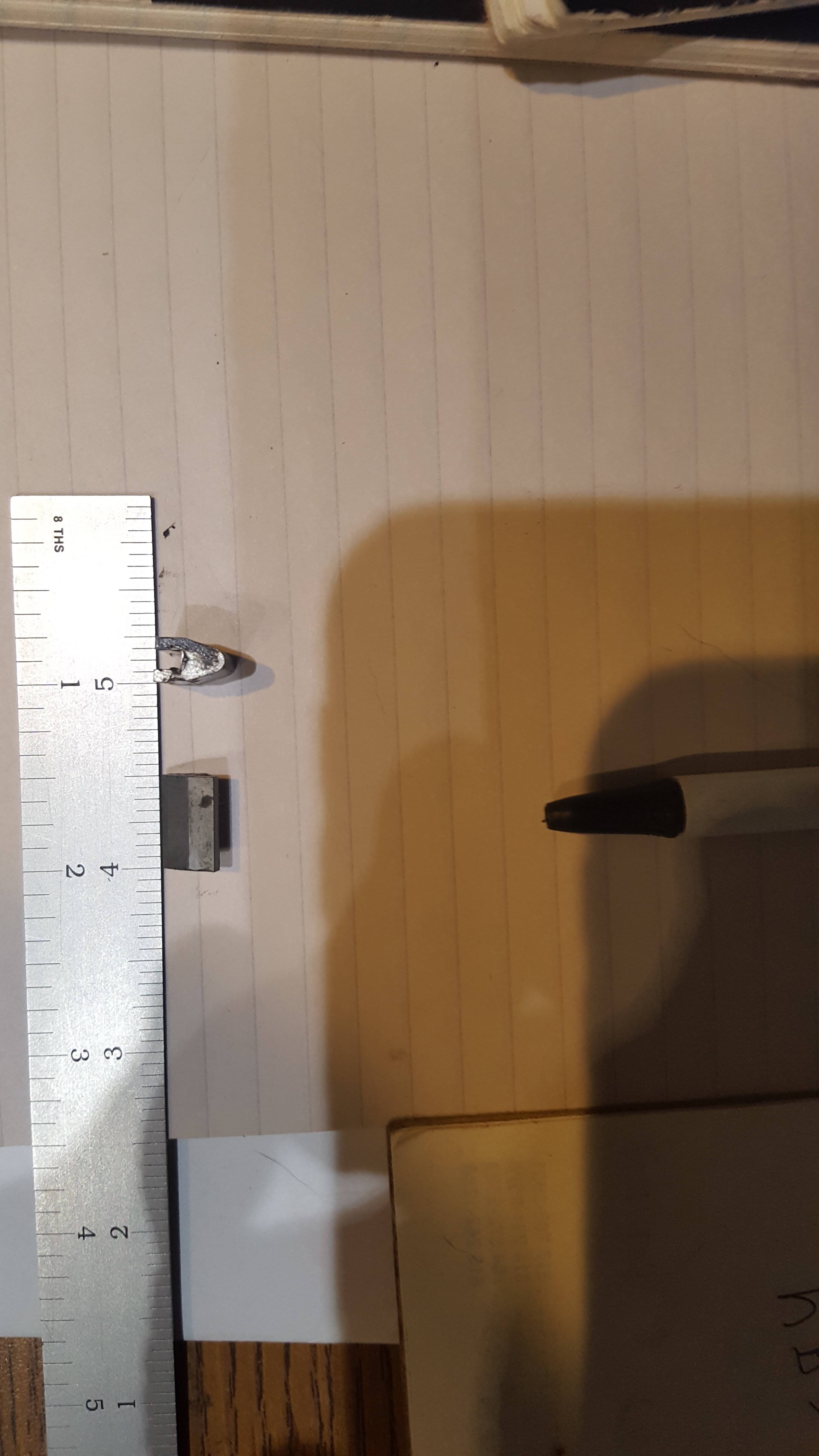

The seat tracks in my 1970 Challenger T/A were very stiff. I am having the seats re-upholstered, so I figured it was a good time to restore the seat tracks. I disassembled the 6 way seat track and found one of the zinc guides had a flange broken off. I did a search of the interweb, and did not find anyone that had these available. Does anyone know of a supplier or does anyone have one they would be willing to part with? See pics.

Also, I didn't see anything on the internet with instructions on how to get the 6 way seat track apart. I discovered you have to push out the studs that bolt the seat track to the body. I used a vise to do this. You have to fully support the flanges on the hat section profile of the track to avoid deforming it. I put a nut on the stud, flush with the end, to prevent damage to the threads. The stud will push out of the plate, but will not push all the way out of the hat section profile (the head hits the vise jaw). However, I found if you keep the stud clamped in the vise, you can wiggle it out of the hat section profile. Once the studs out out, the track will come apart. Be careful not to lose the rollers and guides (as shown in pics). Also, I found 1 stud is shorter than the other 3. You will want to be sure to reinstall it in the same position.

Also, I didn't see anything on the internet with instructions on how to get the 6 way seat track apart. I discovered you have to push out the studs that bolt the seat track to the body. I used a vise to do this. You have to fully support the flanges on the hat section profile of the track to avoid deforming it. I put a nut on the stud, flush with the end, to prevent damage to the threads. The stud will push out of the plate, but will not push all the way out of the hat section profile (the head hits the vise jaw). However, I found if you keep the stud clamped in the vise, you can wiggle it out of the hat section profile. Once the studs out out, the track will come apart. Be careful not to lose the rollers and guides (as shown in pics). Also, I found 1 stud is shorter than the other 3. You will want to be sure to reinstall it in the same position.