B2G707

Well-Known Member

- Joined

- Feb 20, 2017

- Messages

- 64

- Reaction score

- 8

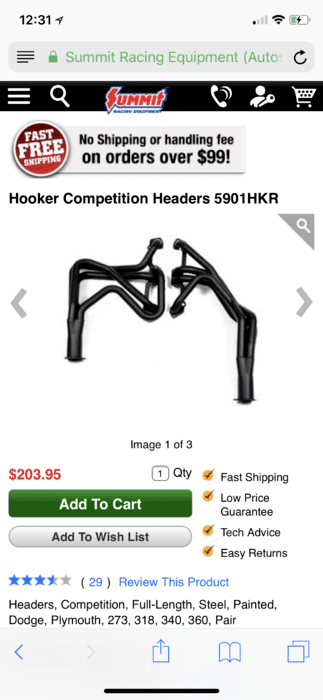

I have a 1970 Challenger with an 360 motor. I purchased the Hooker headers because thats what Summit Racing suggested would be an easy install. This install was anything but easy/simple.

There were numerous issues. From the bolts, hard to bolt on once we got the old headers off. Drive side headers hang very low. Took hours just to line up. Finally when we got the passenger headers on, its pressed up agains the torsion bar and oil filter.

Did anyone else have this problem if you purchaed these headers? And if I return them what headers should I get?

Extremely dissapointed with Hooker Headers!

Any assistance would be truly appreciated. Thank you

There were numerous issues. From the bolts, hard to bolt on once we got the old headers off. Drive side headers hang very low. Took hours just to line up. Finally when we got the passenger headers on, its pressed up agains the torsion bar and oil filter.

Did anyone else have this problem if you purchaed these headers? And if I return them what headers should I get?

Extremely dissapointed with Hooker Headers!

Any assistance would be truly appreciated. Thank you