Righty Tighty

Well-Known Member

Hey all, I brought home a 74 Barracuda a couple weeks ago, and she's fitting right in. I'm doing my best to give her a thorough inspection before *officially* getting out on the road, and naturally there have been some bumps along the way.

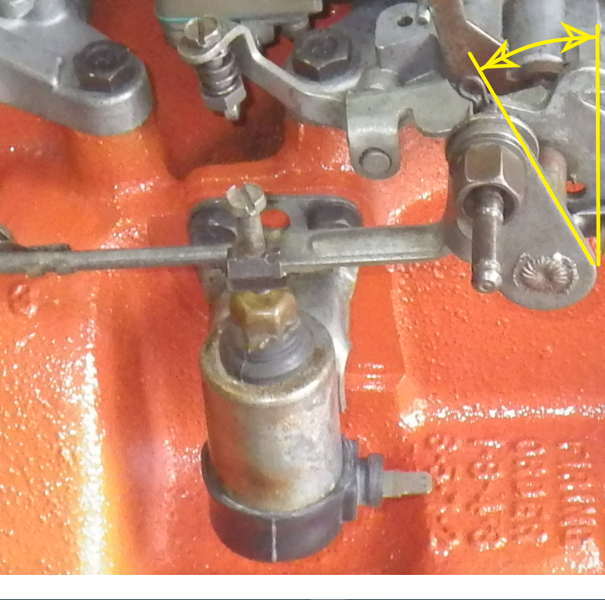

I got it to start after flushing the gas tank, new lines, new plugs, oil, fuel filter and sending unit sock. As the choke opens, the idle steadily increases until what sounds like about 2500 rpm. I haven't connected the tach to find out exactly what the rpm is. I gave a quick check for vacuum leaks, and then checked the initial timing. Over 25 degrees initial (vacuum advance disconnected and plugged). I bumped the timing down to about 10 advanced so that it was drivable enough to flush and bleed the brake system, but even at 10 it sounds a bit high, like maybe 1500 rpm.

The curb idle screw is about as far out as it will go, idle mixture screws are 2 turns out each. I haven't inspected how much of the transfer slots are exposed, but I can see that the outboard throttle plates don't appear to be sticking open. I haven't looked at the distributor yet. I disconnected the brake booster vacuum line and plugged it, no difference.

Here's what I know about the setup that might be relevant:

440 six bbl, 727, headers, power brakes. PCV port is capped, vacuum advance runs to ported vacuum, from what I can tell the fast idle cam isn't hanging up.

What else can I check for?

I got it to start after flushing the gas tank, new lines, new plugs, oil, fuel filter and sending unit sock. As the choke opens, the idle steadily increases until what sounds like about 2500 rpm. I haven't connected the tach to find out exactly what the rpm is. I gave a quick check for vacuum leaks, and then checked the initial timing. Over 25 degrees initial (vacuum advance disconnected and plugged). I bumped the timing down to about 10 advanced so that it was drivable enough to flush and bleed the brake system, but even at 10 it sounds a bit high, like maybe 1500 rpm.

The curb idle screw is about as far out as it will go, idle mixture screws are 2 turns out each. I haven't inspected how much of the transfer slots are exposed, but I can see that the outboard throttle plates don't appear to be sticking open. I haven't looked at the distributor yet. I disconnected the brake booster vacuum line and plugged it, no difference.

Here's what I know about the setup that might be relevant:

440 six bbl, 727, headers, power brakes. PCV port is capped, vacuum advance runs to ported vacuum, from what I can tell the fast idle cam isn't hanging up.

What else can I check for?