Part 2: Working Rearwards...

------------------------------------------------------

Pilot Bearing:

I used this Holley swap pilot bearing after looking through a lot of stock options, looking at sizes of bearings for both 5.9 magnums and Colorados on Rockauto, and measuring my trans and crank. It is basically a needle bearing in a bronze adapter, all you really need. $60

Holley 50378

Flywheel:

Flywheel:

The 5.9 Magnum has a unique balance from all other SBMs, so I had to get one specifically for this engine. I got a standard replacement flywheel off Rockauto. This is a 143T truck flywheel, as necessitated by the truck bellhousing. This bellhousing was never used with a 5.9, but the V6 and 5.2 also use a 143T as it would seem. $125

AMS Automotive Flywheel

Flywheel bolts- use the good stuff, ARP with proper assembly grease and loctite. Standard SBM $19

ARP-240-2801

Clutch and Pressure Plate:

Clutch and Pressure Plate:

This is a weird one, since we are using a bigger flywheel than came with the Colorado but the same Chevy input shaft spline. McLeod has a helpful document

here. I went with a McLeod unit rated for 450 hp, it is not vehicle specific but has the input spline and bolt pattern I need. It is decently stiff but not strenuous at all, it is a hybrid design and it does chatter once in a while at low speed but I may not have given it enough break in. Still happy with it.

MCL-75221

Pressure plate bolts: ARP-130-2201

Slave Cylinder:

Slave Cylinder:

Another interesting one, you can either run an external slave cylinder like originally came on this bellhousing, or run an internal slave like on the Colorado. Using the external slave would require a different front bearing retainer on the trans, so the decision is easy. I got a good quality stock slave on Rockauto. The problem here is getting the correct slave cylinder preload. Yes, preload, not air gap. Most modern cars have preloaded slaves. According to several sources including

fabbotfab.com, the slave should be .100-.200" from bottoming out when installed. Another source says between 1/16 and 1/8, so I shot for .100. Proper preload will prevent the slave from overextending.

Slave Cylinder

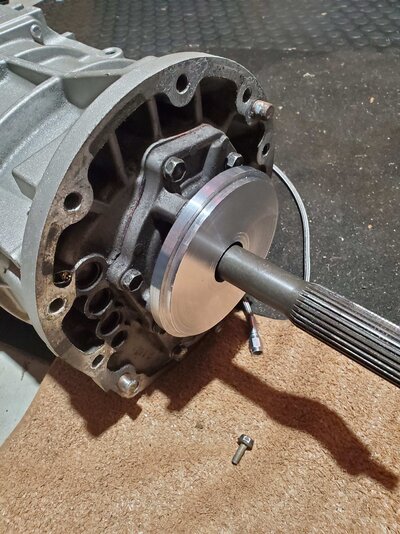

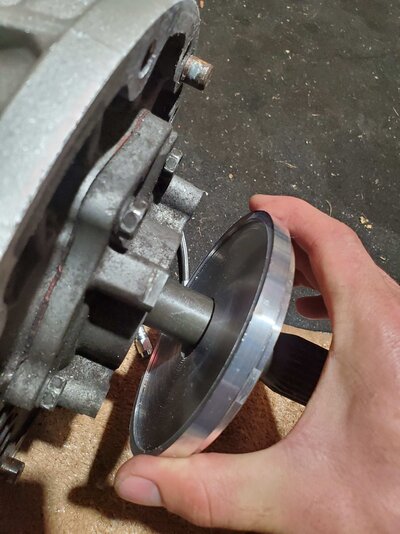

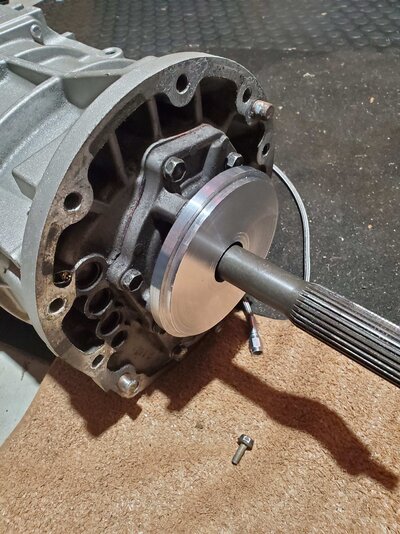

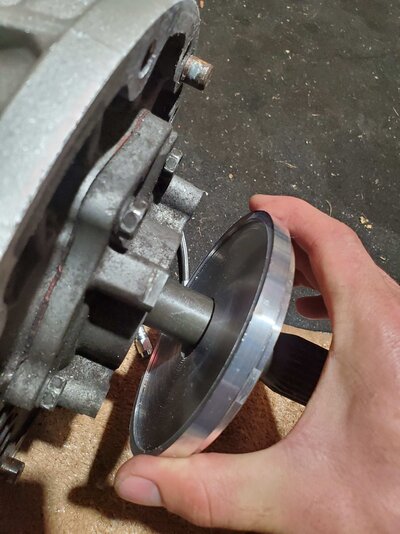

Since the bellhousing and flywheel position are different from the Colorado the slave was made for, you can guess it won't be right the first time. Through many measurements of the trans and engine, I determined a .420" spacer was required underneath the slave. Since this is a concentric slave, it must be centered around the input shaft if you want it to last. The trans has two machined bosses that mate with a bore on the back of the slave to keep it concentric. The bolts alone are not enough to accomplish this. Since the alignment bore on the slave is only ~.080" deep, the spacer must incorporate these features.

The closest available spacer I could find was .500" although this was in the middle of the build so I was looking for something quicker, and it may have been just as much work to modify the off the shelf part as to make a new one. I turned the spacer out of 1/2" aluminum plate and it fitted up well. I did make an error of the front boss being too tall, so I shimmed the slave further out. I ended up with .072" of preload remaining in the slave, which is right on the tight end of the range. It works great!

For hardware, I did buy some longer metric bolts from Advance. I will try to have the size for the full part list.

Trans Mount:

Trans Mount:

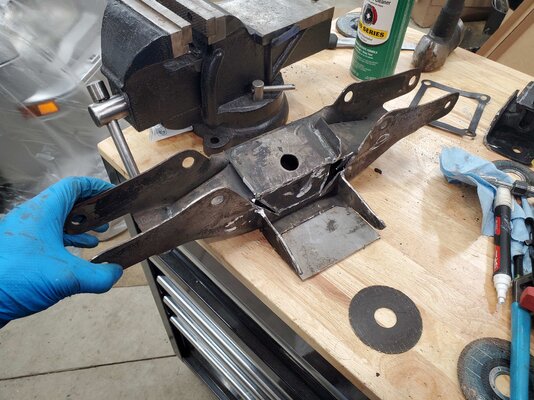

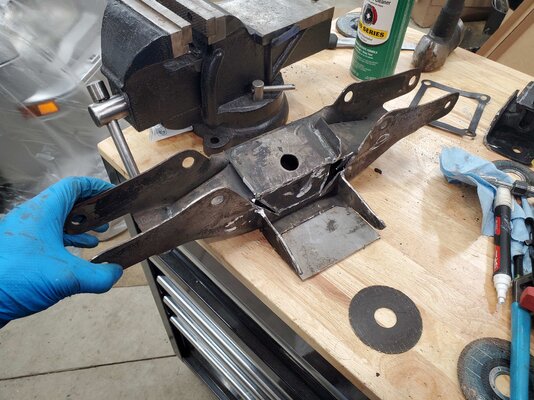

I bought a standard Colorado mount from Rockauto and planned to modify the 727 crossmember to fit. I was able to cut the lateral hole for the 727 rubber mount off. Weld a plate flat on the bottom, and cut and weld the rest to clear the mount. Not too bad if you have a welder. Chrysler was even nice enough to leave it as bare steel for easy welding!

Driveshaft and Yoke:

Driveshaft and Yoke:

A custom transmission swap requires a custom driveshaft. I considered finding a Colorado shaft that would fit, but there is no info available and the tolerance for length is pretty tight.

I was quoted $600-800 for a custom driveshaft from a shop - a little steep for me. Someone online recommended Southwest Speed, and I am quite happy with mine. I got a 3" aluminum shaft for $380 shipped, arrived in about 2-3 days. They have most sizes in 1/2" increments sitting on the shelf, which is amazing for a guy with a car in a million pieces trying to get on the road. It came with the correct yoke for my trans, and a rear u joint. I did have to install the front yoke and swap the rear yoke to fit my 8-3/4, which had the "big dodge" size. It does seem like my front u joint is spitting some grease, so I need to check it out. Otherwise, I am very pleased!

My length was 51.5" from seal to rear u joint face. This equates to I think a 49" driveshaft. They tried to convince me to measure to the trans housing instead of the seal edge, which would have been a mistake. You want 3/4' - 1" of plunge available, and I am dead on 3/4".

Southwest Speed $350

Part 3: Pedals and Hydraulics Coming Soon

Part 3: Pedals and Hydraulics Coming Soon

![20230708_142516[1].jpg 20230708_142516[1].jpg](https://www.forebodiesonly.com/forum/data/attachments/108/108931-e1f3a9584cb91fd9301c2bc392f99e6d.jpg)

![20230708_145255[1].jpg 20230708_145255[1].jpg](https://www.forebodiesonly.com/forum/data/attachments/108/108932-b9d35f84cefb45ca3a25b88da45ca007.jpg)