Mike73Dodge

Well-Known Member

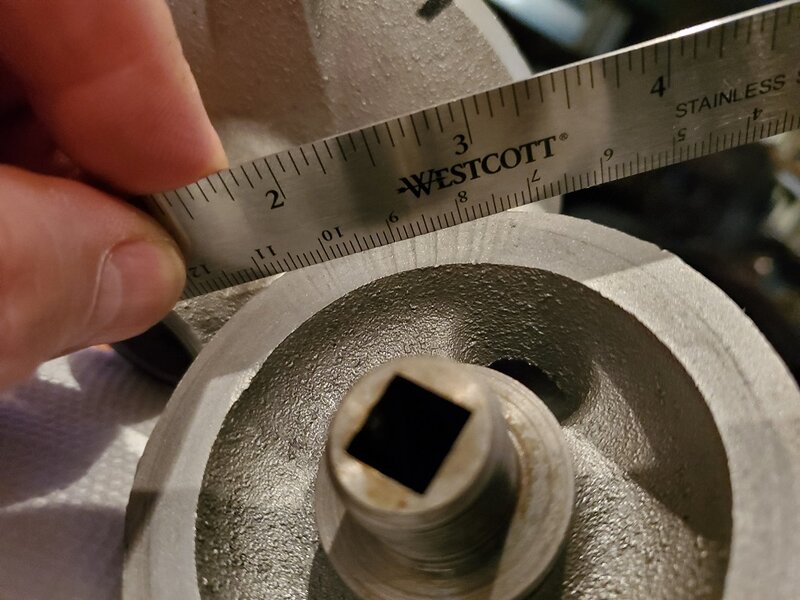

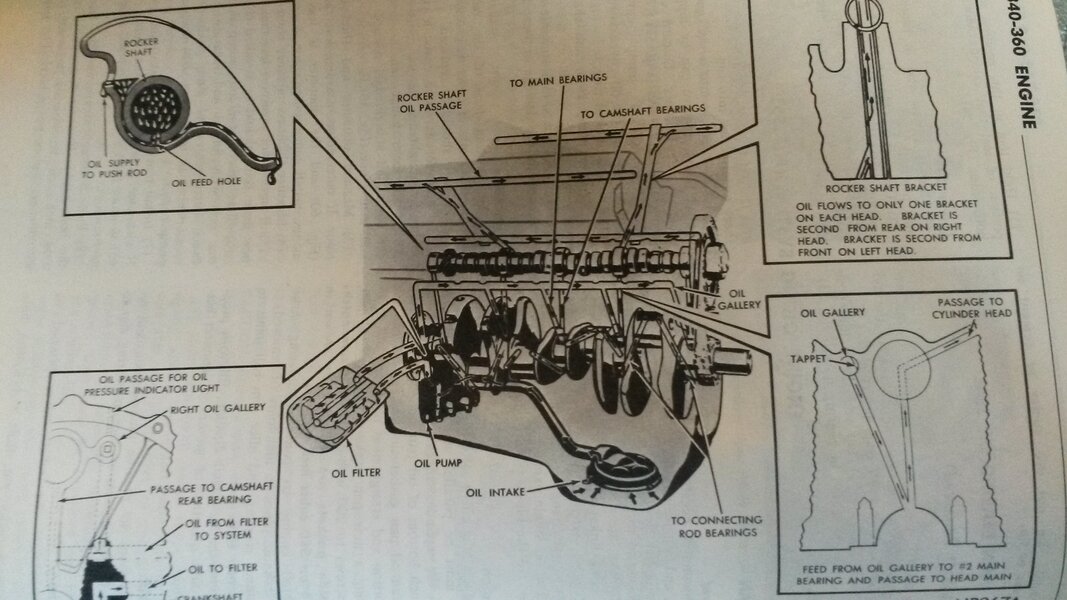

I have a modified 340 with the 90 deg oil filter adapter. It was leaking from under the head of the main bolt. After disassembly I am really not impressed with the design of the whole setup. I am thinking of doing some custom machining of the parts and maybe creating some special bushings to better the design. Has anyone done any custom machining on these parts that prevents leaks?