Hello!

I'm currently restoring a 70challenger.

We are proceeding with the restoration mainly on the rear part, but I have a question for you all.

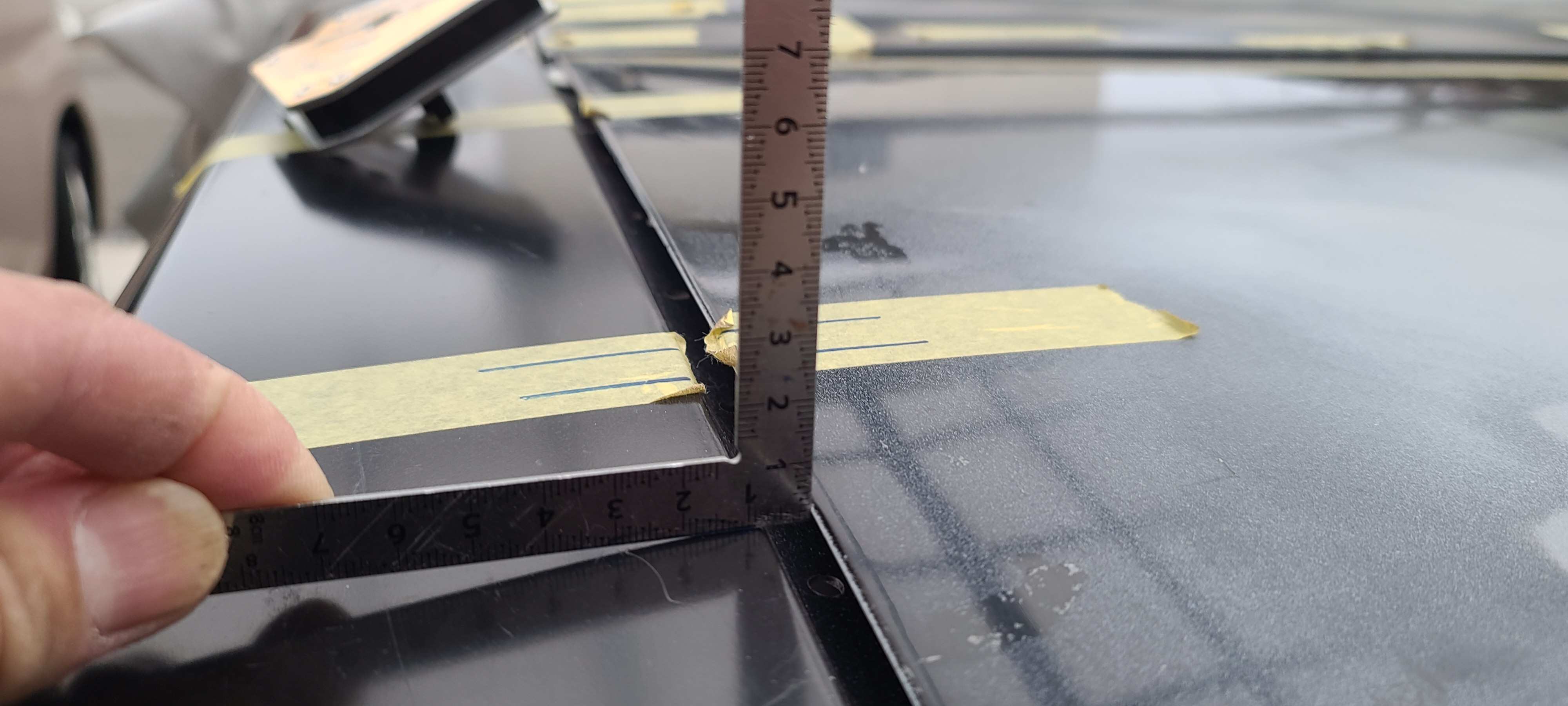

As shown in the photo, there is an approximately 3/16 height difference between the left quarter panel and trunk lid panel.

The quarter panel is made by AMD, and the trunk lid panel is the existing original one.

The curved line on the right quarter panel is the same as the trunk lid panel.

The left quarter panel has not yet been fixed by welding.

In this case, how should I process it to match the curve?

There is a way to adjust the gap of the trunk lid panel and quarter panel on YouTube, but there is no way to adjust the height, so I am asking for advice here.

thank you for reading it until the very end!

I'm currently restoring a 70challenger.

We are proceeding with the restoration mainly on the rear part, but I have a question for you all.

As shown in the photo, there is an approximately 3/16 height difference between the left quarter panel and trunk lid panel.

The quarter panel is made by AMD, and the trunk lid panel is the existing original one.

The curved line on the right quarter panel is the same as the trunk lid panel.

The left quarter panel has not yet been fixed by welding.

In this case, how should I process it to match the curve?

There is a way to adjust the gap of the trunk lid panel and quarter panel on YouTube, but there is no way to adjust the height, so I am asking for advice here.

thank you for reading it until the very end!