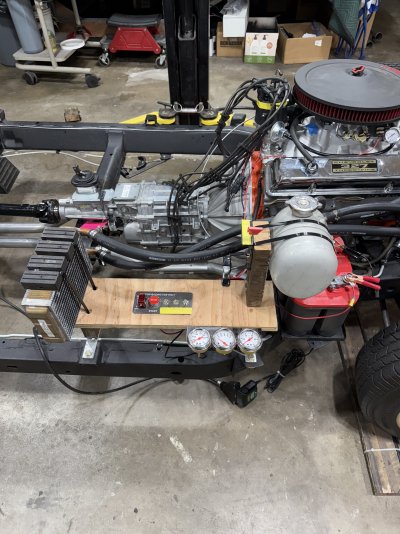

Got it all back together, and tested. Glad I spent the time to set this up. Sounds sweet (cant upload a video). Most importantly, I wanted to test for leaks or other issues. The machine shop forgot to tighten the oil port bolts on the back of the block.....if I had went through all that work to install in the car, then rip the tranny off to find and fix that leak.......I would have been really pissed off, way easier to remove tranny when not in the car.

I'm not perfect either, had a couple of water pump leaks, but that's easy to fix with extra silicon on the bolts.

Question for the steering pump/box guys......with this set up, whether the engine is running or not, the effort it takes to turn the input to the box feels the same, I can only assume, that the pump only works/assists when there is a load on the output shaft (i.e. turning the wheels when its all put back together and weight of car is on tires). I can hear the pump "work" a little when I hit the end stops on the box.

Now to finish the car.........long ways to go on that.

I'm not perfect either, had a couple of water pump leaks, but that's easy to fix with extra silicon on the bolts.

Question for the steering pump/box guys......with this set up, whether the engine is running or not, the effort it takes to turn the input to the box feels the same, I can only assume, that the pump only works/assists when there is a load on the output shaft (i.e. turning the wheels when its all put back together and weight of car is on tires). I can hear the pump "work" a little when I hit the end stops on the box.

Now to finish the car.........long ways to go on that.