I decided (with the help of this chain) that I didn't need a hi-torque starter and went with a regular mini (

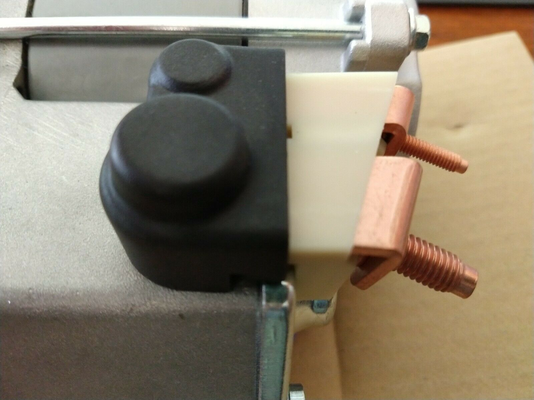

Powermaster PowerMax Plus PWM-9300). It turns over my 440 magnum with ease but the clearance for the connection wires and the block is startlingly close (like 1/4") and incredibly difficult to tighten the connections with the starter in place. I should have removed the starter and attached the wires first (but I was stubborn). I noted this issue with Summit and their answer was clearance for headers. However I think the connections could be put on the underside and the power wire to the starter motor on the top. Whatever, it's done now.

View attachment 93753