moparlee

Well-Known Member

Transmission looks nice. The tail shaft housing looks like buffed bare aluminum. What is the coating on the rest of it?

Transmission looks nice. The tail shaft housing looks like buffed bare aluminum. What is the coating on the rest of it?

How much longer do you think before you can drive it ? Now that you can "see" actual progress, I'm sure your getting anxious.

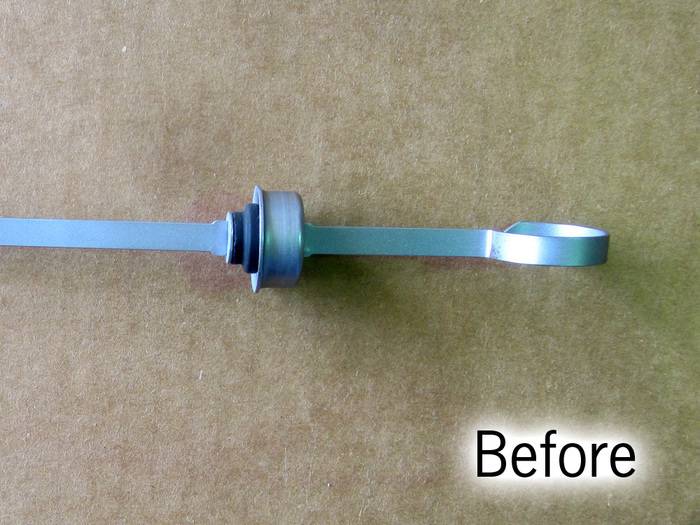

I want to switch gears here (pun intended) to show some before & after pictures of the aluminum section that attaches to the rear of the 727 Transmission. It took the better part of 3 days to restore the aluminum housing to look new again. The configuration and surface of this component is smooth, unlike the textured-rough appearance of the main Transmission housing. You can't use anything abrasive on the smooth casting or it will ruin the smooth finish. After giving it a hot soap bath & rinsed clean, we used a diluted Hydro Fluorhidric-phosphate acid to remove the dark oxidation spots. The entire unit was then massaged with 0000 Steel Wool that was drenched in Mother's Polish. The surface was then polished with a clean soft cloth and wiped with lacquer thinner to remove any remaining residue. Time consuming but worth it! Here are the results:What the history behind the 2 holes in the extension housing 1 have 3 70 units with a smooth taper with no holes & 73 unit off a camper van has the 2 bolts & a huge chunk of cast iron attached was this to dampen the tailshaft harmonics

I want to switch gears here (pun intended) to show some before & after pictures of the aluminum section that attaches to the rear of the 727 Transmission. It took the better part of 3 days to restore the aluminum housing to look new again. The configuration and surface of this component is smooth, unlike the textured-rough appearance of the main Transmission housing. You can't use anything abrasive on the smooth casting or it will ruin the smooth finish. After giving it a hot soap bath & rinsed clean, we used a diluted Hydro Fluorhidric-phosphate acid to remove the dark oxidation spots. The entire unit was then massaged with 0000 Steel Wool that was drenched in Mother's Polish. The surface was then polished with a clean soft cloth and wiped with lacquer thinner to remove any remaining residue. Time consuming but worth it! Here are the results:

I always thought the tabs sticking out(at 10 & 2) were a sign of a rebuilt transmission, if that is the factory way, have learned something new. Thanks

The tail shaft posted in earlier pictures is NOT a correct 1970 version. I screwed up and selected a unit that was used on the later 727 Transmissions. I'll post the restoration process for the "new" unit as it is completed.

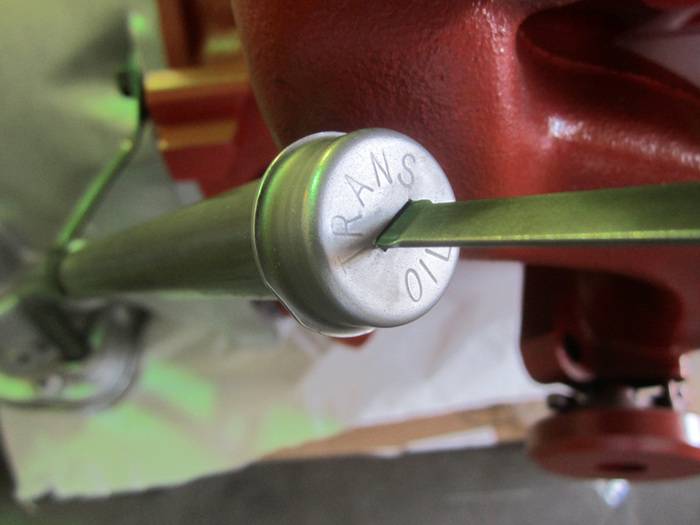

Here are some "Before & After" pictures showing the correct Tail Shaft Housing for the Transmission. I'll post the restoration steps a little later.

I have seen originals with the last 3 digits of the Transmission part number on that area of the gasket. It will be the same 3 digit part number that appears on the Broadcast Sheet. I'll go through my photo archives to find an original photo example.

Here are a few of some small parts. The Dip Stick was actually paint "dipped" like the Factory examples. The Transmission Tube is shown after it was lightly glass beaded and the acid coloring applied to make the metal finish correct and Assembly Line fresh. The Dip Stick itself had to be done in different stages because the assembled components exhibited contrasting colors. The Dip Stick Tube had to be detailed with a small brush to control the color differential between the Tube & attaching Bracket. Also shown are a couple of the Power Steering Hose "before & after" photos.

When you say "acid treatment" will you share what type or kind of "acid" you are using?

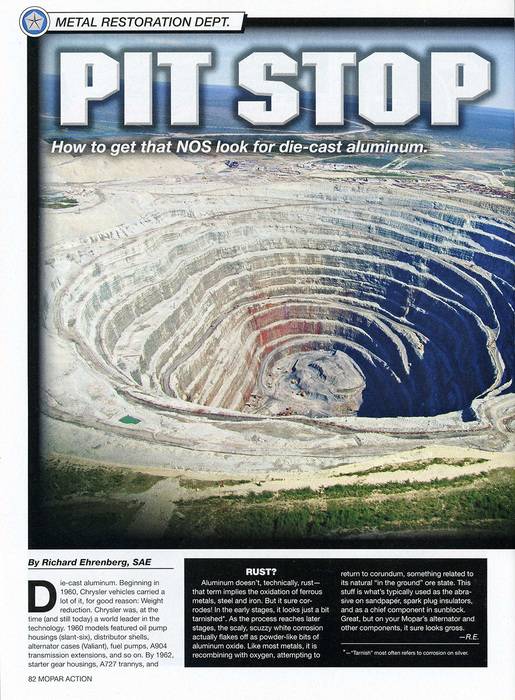

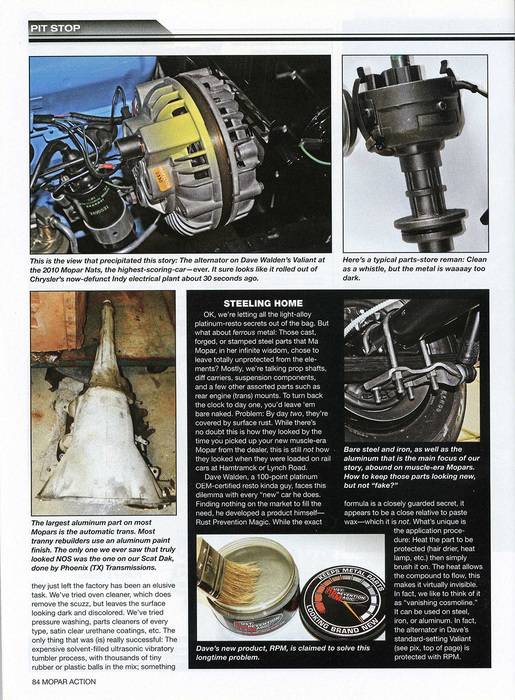

Below is an article that I provided with step by step information about how to restore corroded Aluminum. If the metal is not too severely corroded, you can use these steps to obtain a "new" looking appearance. Each component usually presents a series of different obstacles when attempting to make them look new again. I used products that are easily accessible from many Retail Outlets. They are also shown in the article.

On the Transmission Rear Shaft Housing I recently posted about, the corrosion was too severe for the process illustrated below, so I had to use LOW PRESSURE Glass beading to remove the heavy oxidation. I'll post the step by step procedure for that method (with photos) to illustrate the process.

I always thought the tabs sticking out(at 10 & 2) were a sign of a rebuilt transmission, if that is the factory way, have learned something new. Thanks

Thanks Dave. Really appreciate you taking the time to post that !!

The tail shaft posted in earlier pictures is NOT a correct 1970 version........

Now that you can "see" actual progress, I'm sure your getting anxious.