the 1972 Chrysler FSM shows schematic an alternator bypass wire -my 72 T&C had the bypass. It splits the current in 1/2. If you want to get anal what is the resistance in ohms of the ammeter E=IR and we can calculate the very minor difference in current flow between the 2 wires. Please post the math as I might be "schooled" in electrical engineering.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BY passing charging gauge 70 challenger

- Thread starter wantonebadebody

- Start date

72RoadRunnerGTX

Well-Known Member

Ok, let’s get anal, start by clarifying your term “alternator by-pass”. Page 8-166 of the ’72 Chrysler Plymouth FSM? Most Chrysler C-bodies from that time used “shunted” ammeters with 20 ga wires running to the C-body ammeter. That is not the same ammeter movement or charging system used in A, B & E body platforms. No comparison there. The factory C-body “by-pass” you described acts as the shunt for that system. No parallel by-passes, as described in this thread, from the factory assembly line. The B-body fleet bulkhead by-pass had the original dash harness ammeter leads cut off and taped back with direct runs from the alternator and fusible link, grommeted through the firewall, no shunts.

That said, there was a C-body factory bulkhead connection by-pass “recall” later in the seventies that involved installing a pre-made additional 12 ga wire run directly from the alternator to the fuse box “Batt” terminal. Installed at the dealers, paid .3 of an hour to install, ask me how I know that. It had a molded oval plastic gromet attached designed to route through the removed oval clutch rod hole plug in the firewall.

Parallel runs? Doesn’t take much calculation to understand that running different sized wires over a given distance, with multiple corroded terminations/disconnects on the smaller wire run, the voltage drop will be nowhere near equal for each run, the resulting current split will not be anywhere near equally divided in half.

“If you want to get anal what is the resistance in ohms of the ammeter E=IR and we can calculate the very minor difference in current flow between the 2 wires.”

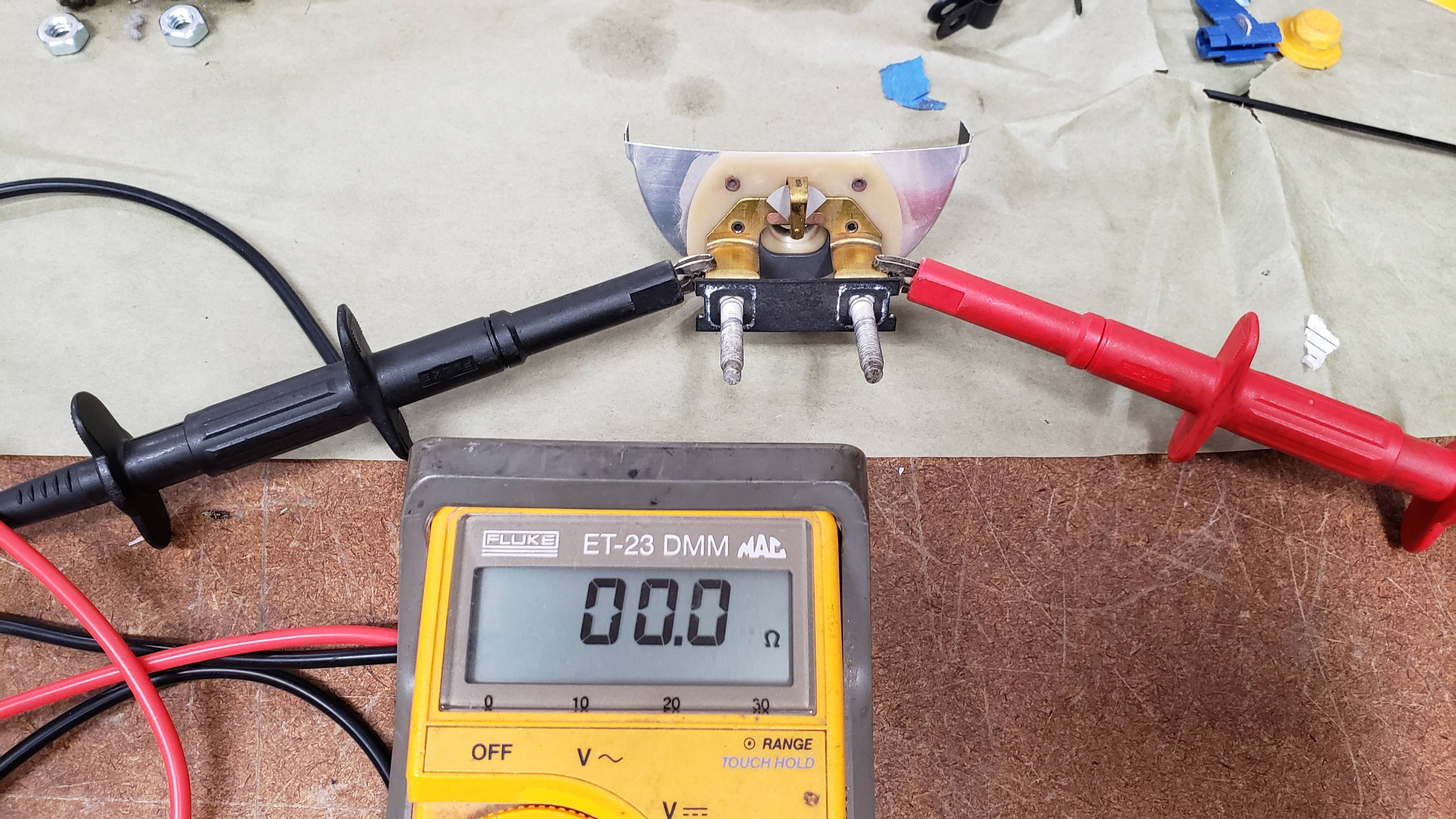

How about we just measure it?

That said, there was a C-body factory bulkhead connection by-pass “recall” later in the seventies that involved installing a pre-made additional 12 ga wire run directly from the alternator to the fuse box “Batt” terminal. Installed at the dealers, paid .3 of an hour to install, ask me how I know that. It had a molded oval plastic gromet attached designed to route through the removed oval clutch rod hole plug in the firewall.

Parallel runs? Doesn’t take much calculation to understand that running different sized wires over a given distance, with multiple corroded terminations/disconnects on the smaller wire run, the voltage drop will be nowhere near equal for each run, the resulting current split will not be anywhere near equally divided in half.

“If you want to get anal what is the resistance in ohms of the ammeter E=IR and we can calculate the very minor difference in current flow between the 2 wires.”

How about we just measure it?

72 Roadrunner GTX, I am new to the forum and also having issues on this topic, and it appears your are very knowledgeable on it. To save time and reduce unclear back and forth on the forum, is it prohibited to discuss outside the forum via phone conversation, or is it okay? If it is okay, is that something you would be willing to do? I want to make sure I don’t fry something else!!!

Thank you!

Thank you!

terrywalker

Well-Known Member

- Joined

- Aug 31, 2013

- Messages

- 590

- Reaction score

- 409

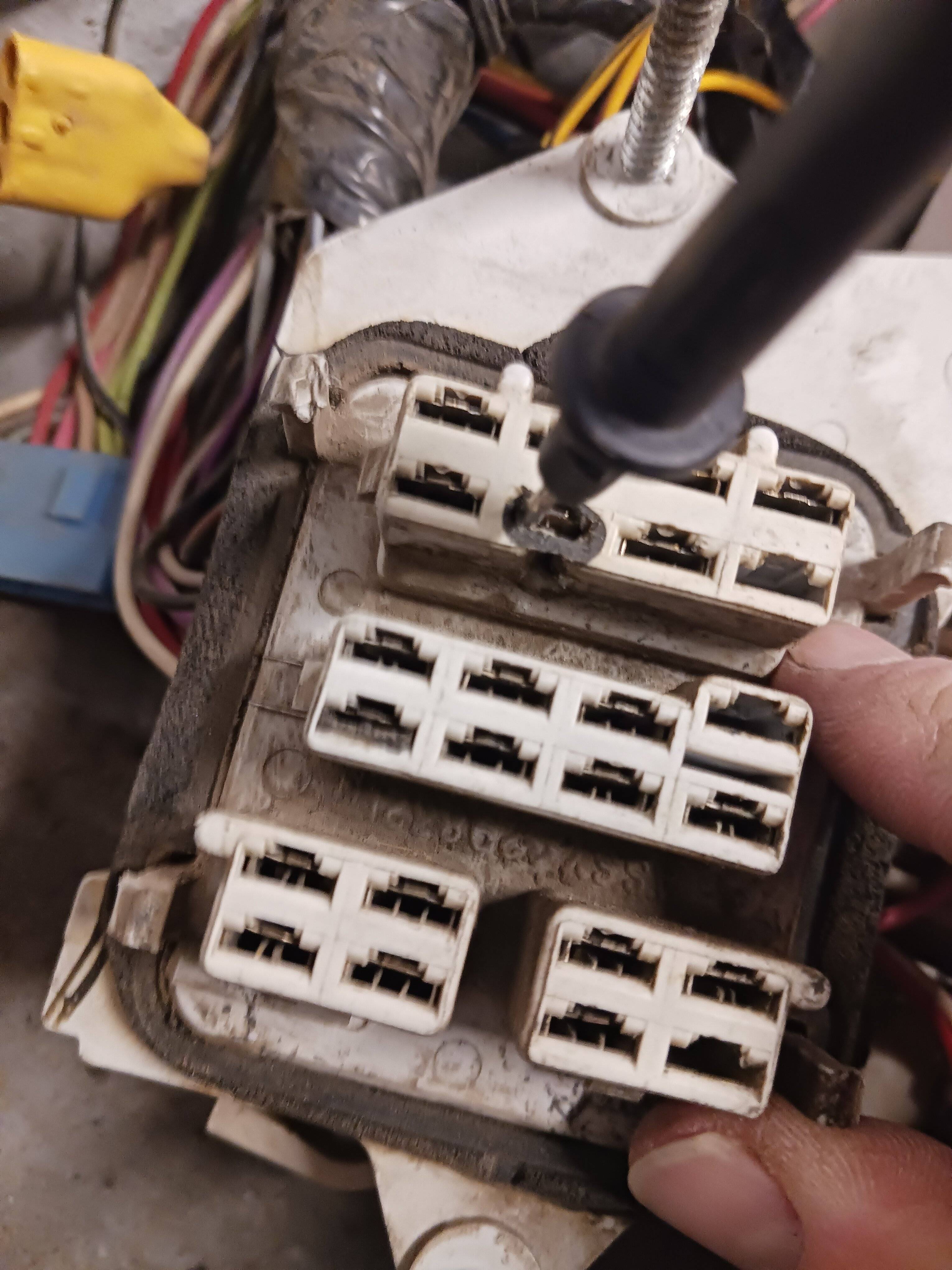

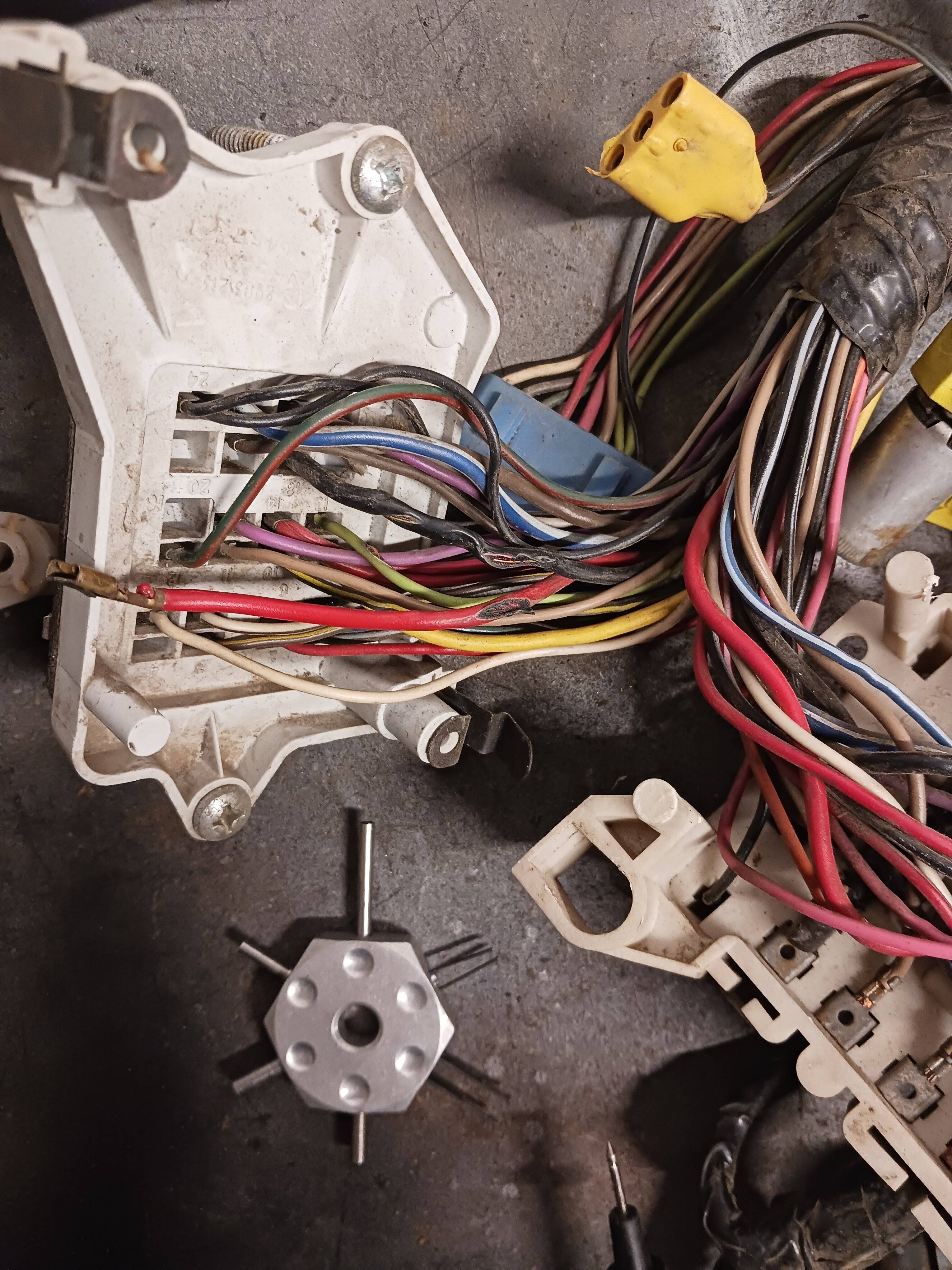

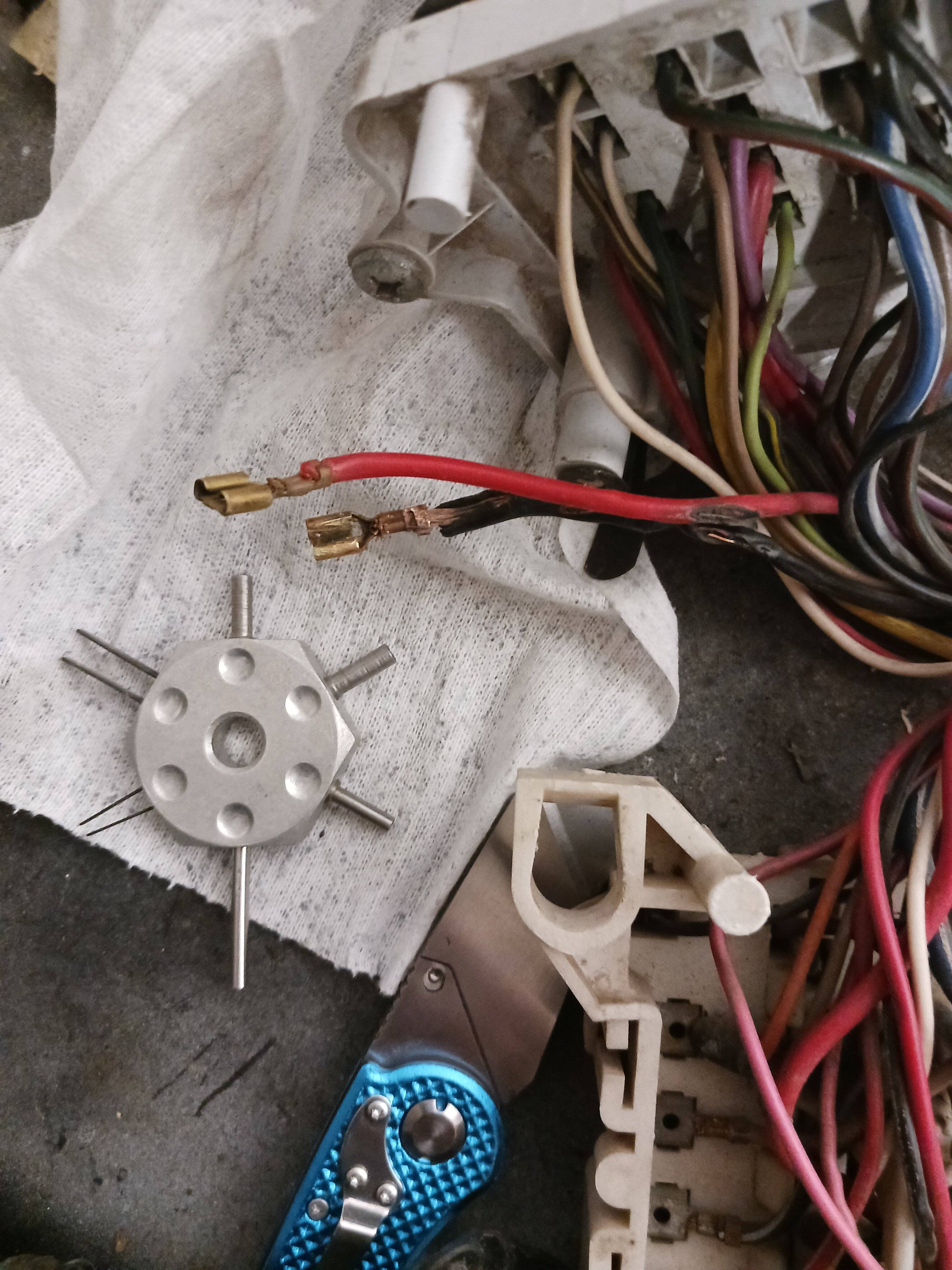

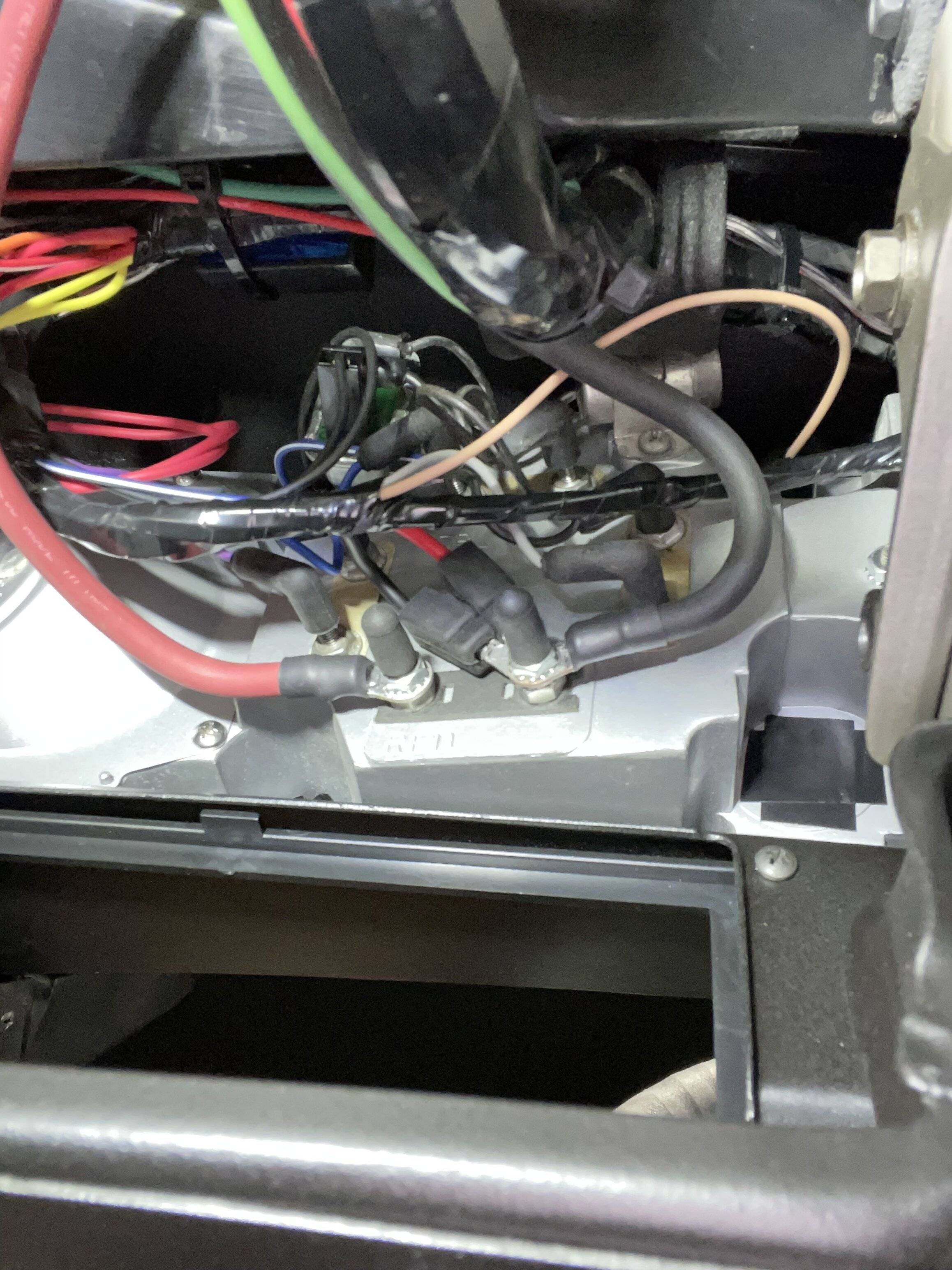

This is a timely topic to return to as I ran into a problem yesterday while checking my dash wire harness from my 72 Challenger as it's removed from the car. I found the black wire melted to the red wire. See photo. I have 3 spare bulkhead connectors but am not sure if I want to still use the ammeter. I've been thinking of a voltmeter in its place. I'm not sure if I want to run these 2 wires through bulkhead connector now. i knew something was wrong when I noticed the white plastic melted by the terminal on engine compartment side. I'm glad I checked it out.

Terry W.

Terry W.

Challenger RTA

Well-Known Member

It's always just a matter of time! even with a new harness. At lest you caught the problem before it became disaster. Also check the foot dimmer switch.

Last edited:

72RoadRunnerGTX

Well-Known Member

Doesn’t have to be, address the real weaknesses in the original design, don’t misplace any add-on loads. Always know the state of your charging system and related conductors/connections.

Yes, current repo harness are just copies of the originals, including the original flaws. First thing I do is cut them open and upsize the charge circuit wires, extending them directly through to the ammeter via a grommet, no need for any disconnects at the bulkhead.

Yes, current repo harness are just copies of the originals, including the original flaws. First thing I do is cut them open and upsize the charge circuit wires, extending them directly through to the ammeter via a grommet, no need for any disconnects at the bulkhead.

terrywalker

Well-Known Member

- Joined

- Aug 31, 2013

- Messages

- 590

- Reaction score

- 409

I'm definitely not running the black and red wires through the bulkhead connector and I will probably go a heavier gauge wire. I also don't like the crimp connectors and I like to use the solder type connectors. I also believe in fuses and fusible links. It pays to check the harnesses. This could have been a disaster.

Terry W.

Terry W.

terrywalker

Well-Known Member

- Joined

- Aug 31, 2013

- Messages

- 590

- Reaction score

- 409

@72RoadRunnerGTX . Do you install a fusible link or a fuse in the new wires you run when replacing the red and black 12 gauge wires directly? I'm thinking of using 10 or 8 gauge wire.

Terry W.

Terry W.

Challenger RTA

Well-Known Member

You might consider using CHR2889809_FOOT_PUMP_WASHER_GROMMET_2000__05967.

10 gauge or 8 gauge might fit through. I would protect it some how,fusible link,fuse,circuit breaker. each one if you run 2

10 gauge or 8 gauge might fit through. I would protect it some how,fusible link,fuse,circuit breaker. each one if you run 2

Last edited:

72RoadRunnerGTX

Well-Known Member

I’ll use 8ga for the charge circuit wires, and a single 12ga fusible link at the starter relay as I plan for running high output alternators and several additional non-stock loads, all on the alternator side of the ammeter. Another fusible link at the alternator is not necessary.@72RoadRunnerGTX . Do you install a fusible link or a fuse in the new wires you run when replacing the red and black 12 gauge wires directly? I'm thinking of using 10 or 8 gauge wire.

Terry W.

terrywalker

Well-Known Member

- Joined

- Aug 31, 2013

- Messages

- 590

- Reaction score

- 409

Great information/photos on the fusible links. Thank you.

Terry W.

Terry W.

MoparCarGuy

Well-Known Member

- Joined

- Jun 28, 2020

- Messages

- 1,023

- Reaction score

- 991

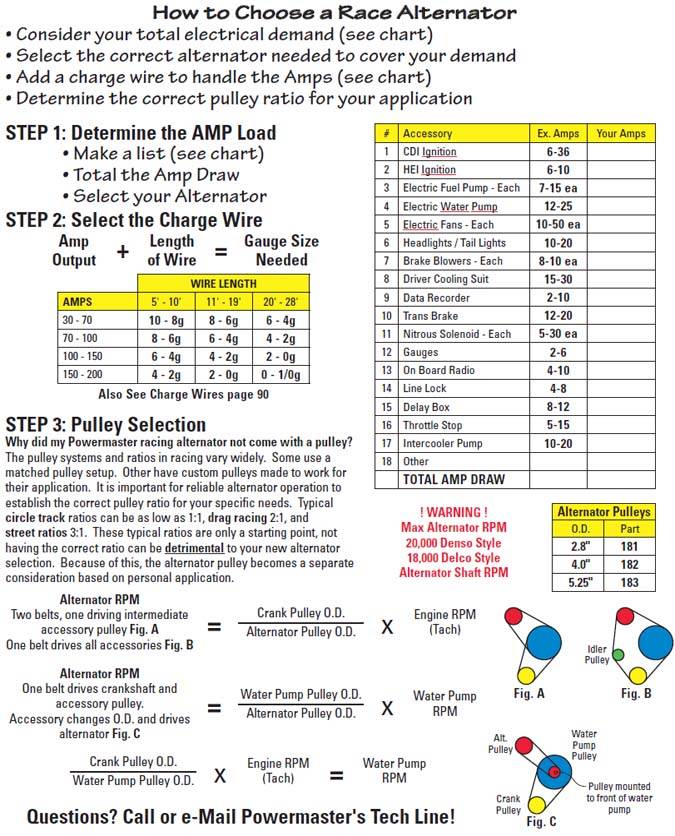

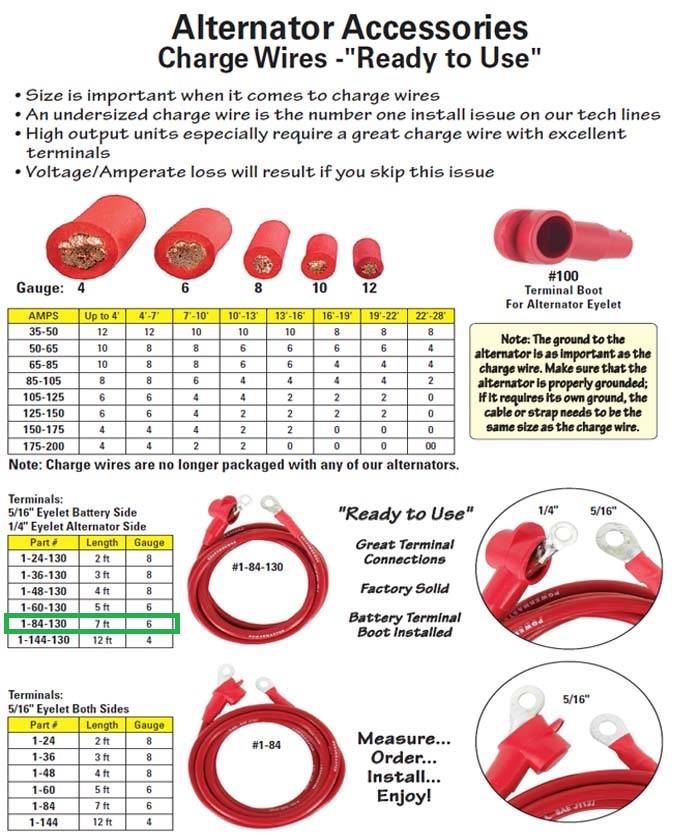

I wholeheartedly agree with upgrading the factory charging circuit and bypassing the factory electrical bulkhead and ammeter. Powermaster provides the two guides below to assist with determining what size alternator is correct to support your amperage demand (load) and select the correct size charging wire. You can also verify with a clamp-on ammeter (Amprobe) to see exactly how many amps you are drawing for all of your accessories. Electric fuel pumps, fans, line-lock, ignition boxes, etc. add to the overall load and really need a larger capacity alternator. The factory alternator were hard-pressed to supply your headlights at night without dimming and brightening with throttle application.

A Powermaster 7-foot charging circuit cable (ammeter bypass) can be run directly to the starter relay and should be approximately 8 American Wire Gauge (AWG) to support a 50 to 95A load. A 6AWG is even better. The fusible link discussed earlier in this thread should be the last segment to the starter relay and four sizes smaller than the charging cable. It must be added to the Powermaster charging cable though . 72RoadRunnerGTX's example of 8AWG with a 12AWG fusible link is perfect for most cars up to 95A. <<Note: the fusible link cannot be a standard insulated piece of wire. The insulation on a fusible link is designed to support the high temperature when overloaded and will melt versus burn.>>

. 72RoadRunnerGTX's example of 8AWG with a 12AWG fusible link is perfect for most cars up to 95A. <<Note: the fusible link cannot be a standard insulated piece of wire. The insulation on a fusible link is designed to support the high temperature when overloaded and will melt versus burn.>>

I am installing a Powermaster 75691 (95A) 1-wire alternator (internal regulator) this weekend with a Powermaster 6AWG charging cable and 10AWG fusible link. The charging cable will be routed from the alternator down to the framerail and forward to the radiator support's lower section and across to the driver's inner fender and terminate at the starter relay.

I am running Holley Terminator X Stealth EFI and discovered my low amp factory alternator was overcharging (15.4 to 15.7VDC). The EFI's handheld LCD programmer/monitor flickered for Battery Voltage showing yellow to red warning at idle. Without that indication I would not have known I was overcharging my battery.

I had bypassed my ammeter years ago with a 10AWG wire and 6AWG fusible link but did not install a voltmeter at that time. After this alternator upgrade I will also mofidy my factory Rallye cluster's ammeter to convert it to a SunPro CP7985 voltmeter. Goal is to monitor the charging voltage without looking at the EFI's handheld LCD. The SunPro needle sweeps the correct direction and the numeral font is close enough for me. I will likely black out the blue line and attached the factory ammeter needle to the SunPro needle. The below gauge face and a picture of another forum member's modded 4-pod Rallye cluster.

I am also installing a Real Time Engineering (RTE) Instrument Voltage Regulator (IVR3) to ensure all of my gauges are receiving the proper 5VDC. Bye bye 54 year old original mechanical IVR.

I will report back after the alternator install but I fully expect to have a rock solid 14.5 to 14.8 VDC when completed.

EDIT: I will create a new thread for anyone interested in this alternator upgrade and instrument voltage regulator upgrade with voltmeter.

A Powermaster 7-foot charging circuit cable (ammeter bypass) can be run directly to the starter relay and should be approximately 8 American Wire Gauge (AWG) to support a 50 to 95A load. A 6AWG is even better. The fusible link discussed earlier in this thread should be the last segment to the starter relay and four sizes smaller than the charging cable. It must be added to the Powermaster charging cable though

I am installing a Powermaster 75691 (95A) 1-wire alternator (internal regulator) this weekend with a Powermaster 6AWG charging cable and 10AWG fusible link. The charging cable will be routed from the alternator down to the framerail and forward to the radiator support's lower section and across to the driver's inner fender and terminate at the starter relay.

I am running Holley Terminator X Stealth EFI and discovered my low amp factory alternator was overcharging (15.4 to 15.7VDC). The EFI's handheld LCD programmer/monitor flickered for Battery Voltage showing yellow to red warning at idle. Without that indication I would not have known I was overcharging my battery.

I had bypassed my ammeter years ago with a 10AWG wire and 6AWG fusible link but did not install a voltmeter at that time. After this alternator upgrade I will also mofidy my factory Rallye cluster's ammeter to convert it to a SunPro CP7985 voltmeter. Goal is to monitor the charging voltage without looking at the EFI's handheld LCD. The SunPro needle sweeps the correct direction and the numeral font is close enough for me. I will likely black out the blue line and attached the factory ammeter needle to the SunPro needle. The below gauge face and a picture of another forum member's modded 4-pod Rallye cluster.

I am also installing a Real Time Engineering (RTE) Instrument Voltage Regulator (IVR3) to ensure all of my gauges are receiving the proper 5VDC. Bye bye 54 year old original mechanical IVR.

I will report back after the alternator install but I fully expect to have a rock solid 14.5 to 14.8 VDC when completed.

EDIT: I will create a new thread for anyone interested in this alternator upgrade and instrument voltage regulator upgrade with voltmeter.

Last edited:

MoparCarGuy

Well-Known Member

- Joined

- Jun 28, 2020

- Messages

- 1,023

- Reaction score

- 991

Nice work on the mechanical and soldered connectors with heat-shrink tubing. Very professional installation!I’ll use 8ga for the charge circuit wires, and a single 12ga fusible link at the starter relay as I plan for running high output alternators and several additional non-stock loads, all on the alternator side of the ammeter. Another fusible link at the alternator is not necessary.

View attachment 102405Another

72RoadRunnerGTX

Well-Known Member

To clarify one point, not to get another ammeter vs. voltmeter debate started, I by-pass everything but a perfectly good ammeters on my stock or somewhat modified loaded cars. I’ll take the real-time information the ammeter can provide over a simple voltmeter any-day.

terrywalker

Well-Known Member

- Joined

- Aug 31, 2013

- Messages

- 590

- Reaction score

- 409

@72RoadRunnerGTX . Are the ring terminals and butt connectors you used on your wiring crimp/heatshrink type or solder terminals/butt connectors with your own heat shrink put on? They look nice.

Terry W.

Terry W.

72RoadRunnerGTX

Well-Known Member

All terminations pictured are bare crimp-on ring or butt connectors, crimped and soldered, with appropriately sized shrink tubing added. Again, no unnecessary disconnects of any kind in the charge circuit.

moparlee

Well-Known Member

Terry, maybe you already know this, but the green wire in photo 3 is also burned.This is a timely topic to return to as I ran into a problem yesterday while checking my dash wire harness from my 72 Challenger as it's removed from the car. I found the black wire melted to the red wire. See photo. I have 3 spare bulkhead connectors but am not sure if I want to still use the ammeter. I've been thinking of a voltmeter in its place. I'm not sure if I want to run these 2 wires through bulkhead connector now. i knew something was wrong when I noticed the white plastic melted by the terminal on engine compartment side. I'm glad I checked it out.

Terry W.

View attachment 102399

View attachment 102400

View attachment 102401

View attachment 102402

terrywalker

Well-Known Member

- Joined

- Aug 31, 2013

- Messages

- 590

- Reaction score

- 409

Yes, I saw that and it will be repaired. I appreciate everyone's replies. Thank you.

Terry W.

Terry W.

340challconvert

Well-Known Member

72RoadRunnerGTX

Well-Known Member

Funny how that Mad Electrical article about later seventies Dodge truck “plastic framed” ammeters always gets conflated with every other Chrysler ammeter application. Read the introduction carefully, passenger car ammeters are not constructed the same, with good well-maintained connections/insulators, correctly loaded, they will not spontaneously “melt-down” for no reason whatsoever.

Big deference between the truck ammeter from the mid-later seventies and the passenger car ammeters from the sixties/early seventies. Both systems have nothing in common with the generator-based charging systems from 1920’s Ford Model As, there is no comparison.

Big deference between the truck ammeter from the mid-later seventies and the passenger car ammeters from the sixties/early seventies. Both systems have nothing in common with the generator-based charging systems from 1920’s Ford Model As, there is no comparison.

Last edited:

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 9

- Views

- 2K

- Replies

- 16

- Views

- 2K