Hello again!

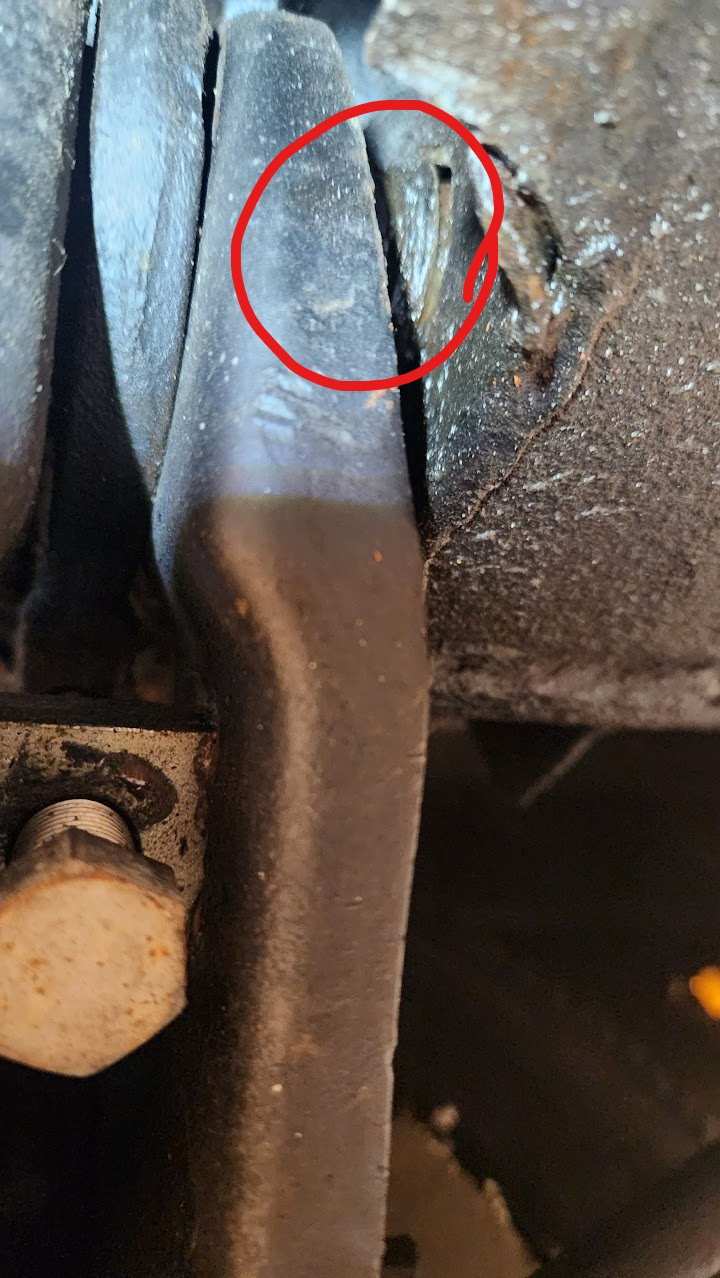

I've recently been working through an issue where my drivers side wheel had a lot of negative camber. I ended up swapping all the ball joints and Upper Arm, only for it to stay the same. Got it on a lift and realized whats going on. The area where the torsion bar meets with the k-member seems to be broken and the frame itself is separating at a seam. I'm no expert so I'm here for advice. I'm thinking based on the damage, I need to weld up the hole and split in the frame, and replace/repair the k-member? I'm thinking of just swapping it for a qa1 but would like some input. Ive attached pictures to hopefully add some insight.

Basically if you get a crowbar between the lower arm and the frame, you can pull that crack apart and flex the entire k member. the lower arm is hitting the frame and is sticking out about 2cm more on the drivers side than the passengers because the damage.

I've recently been working through an issue where my drivers side wheel had a lot of negative camber. I ended up swapping all the ball joints and Upper Arm, only for it to stay the same. Got it on a lift and realized whats going on. The area where the torsion bar meets with the k-member seems to be broken and the frame itself is separating at a seam. I'm no expert so I'm here for advice. I'm thinking based on the damage, I need to weld up the hole and split in the frame, and replace/repair the k-member? I'm thinking of just swapping it for a qa1 but would like some input. Ive attached pictures to hopefully add some insight.

Basically if you get a crowbar between the lower arm and the frame, you can pull that crack apart and flex the entire k member. the lower arm is hitting the frame and is sticking out about 2cm more on the drivers side than the passengers because the damage.