greatscot3

Well-Known Member

- Joined

- Oct 17, 2009

- Messages

- 89

- Reaction score

- 24

Hello

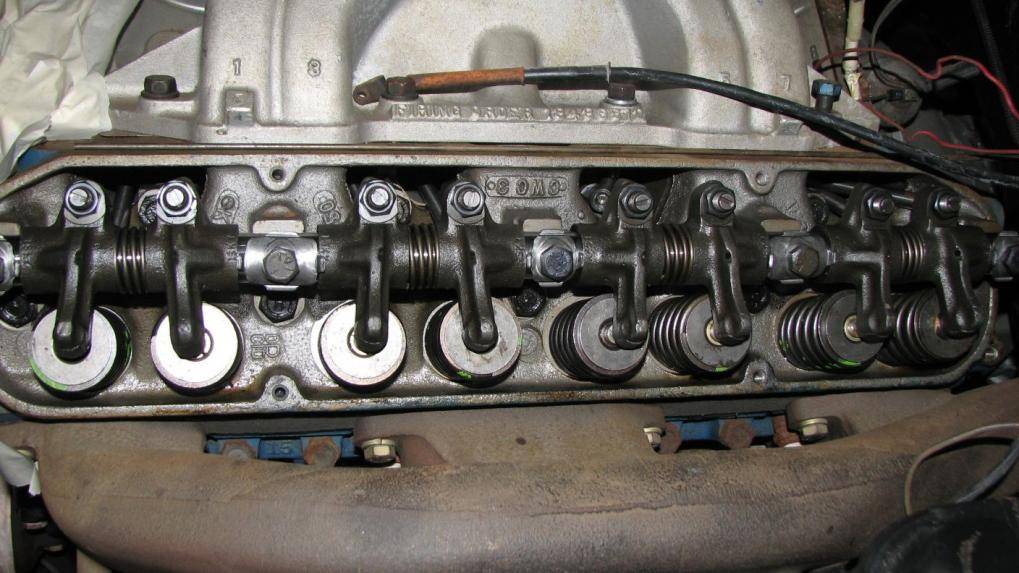

I am looking for help with a valve train issue I am having with my 69 440.

I have been trying to shoehorn my rocker shafts, arms, springs and spacers back onto the heads and I am noticing a couple things that are not right with it.

I am running Mopar Performance rocker shafts and Isky 1604 iron rocker arms with adjusting studs and lock nuts.

After setting up the left and right (intake and exhaust) rocker arms on the driver's side shaft with the spacer springs, I am having a hell of a time getting the rocker arm tips to line up in the centers of the valve stems. The Mopar Performance bolts and half moon washers or spacers look different to me from one side to the other and it is very hard to get them to tighten down and lay flat on the rocker shafts and separate the rocker arms properly.

I went to Isky's site and saw that the rocker arms that I have are sold with spacer springs and I wonder if using stock spacer springs might be the problem.

Has anyone else encountered a similar problem?

Thanks for any help you might have.

I am looking for help with a valve train issue I am having with my 69 440.

I have been trying to shoehorn my rocker shafts, arms, springs and spacers back onto the heads and I am noticing a couple things that are not right with it.

I am running Mopar Performance rocker shafts and Isky 1604 iron rocker arms with adjusting studs and lock nuts.

After setting up the left and right (intake and exhaust) rocker arms on the driver's side shaft with the spacer springs, I am having a hell of a time getting the rocker arm tips to line up in the centers of the valve stems. The Mopar Performance bolts and half moon washers or spacers look different to me from one side to the other and it is very hard to get them to tighten down and lay flat on the rocker shafts and separate the rocker arms properly.

I went to Isky's site and saw that the rocker arms that I have are sold with spacer springs and I wonder if using stock spacer springs might be the problem.

Has anyone else encountered a similar problem?

Thanks for any help you might have.