Tirekickertoo

Well-Known Member

Hi Everyone,

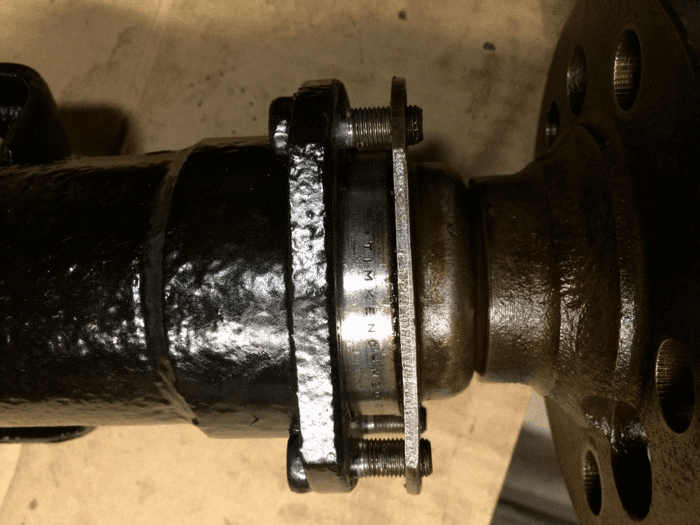

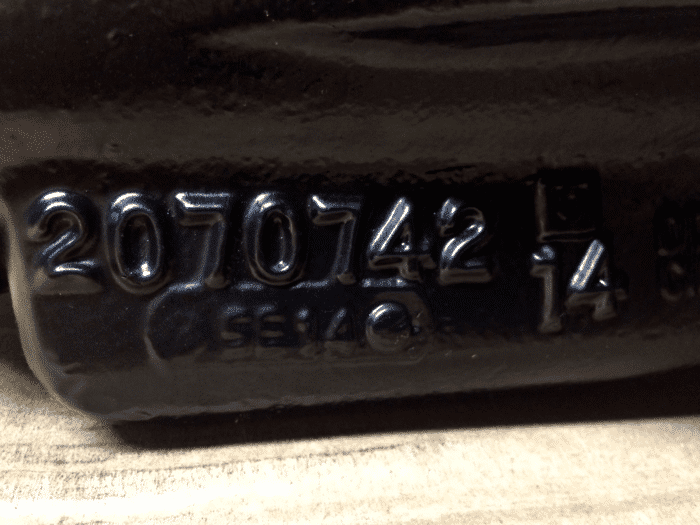

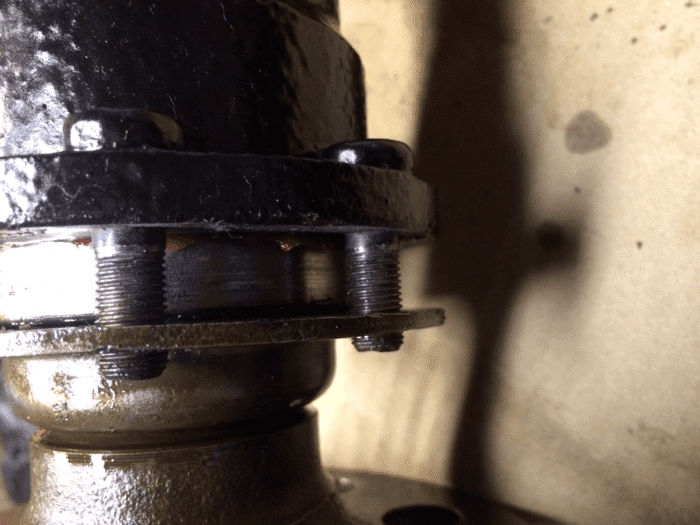

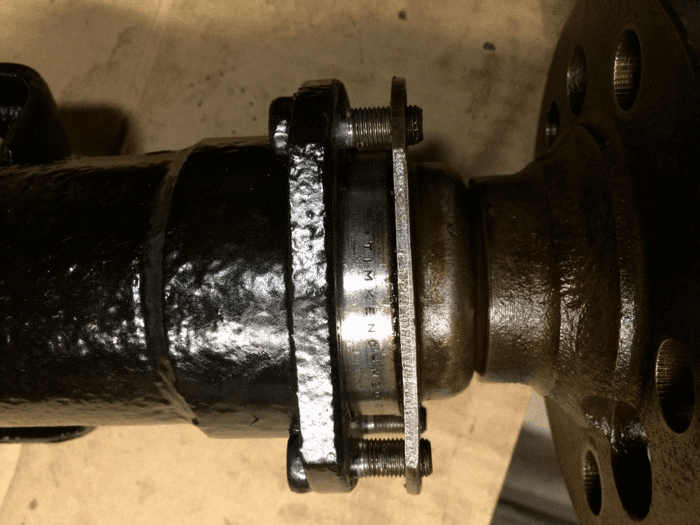

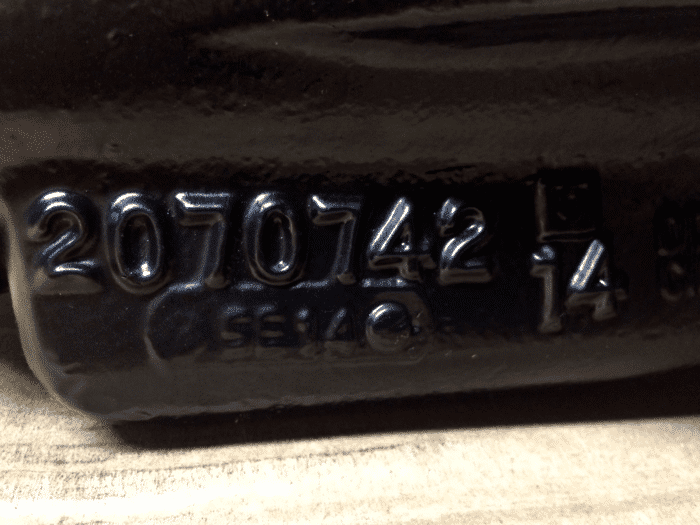

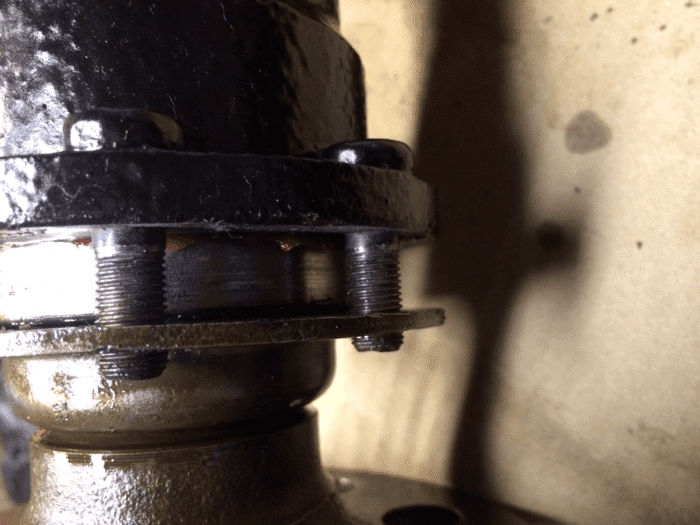

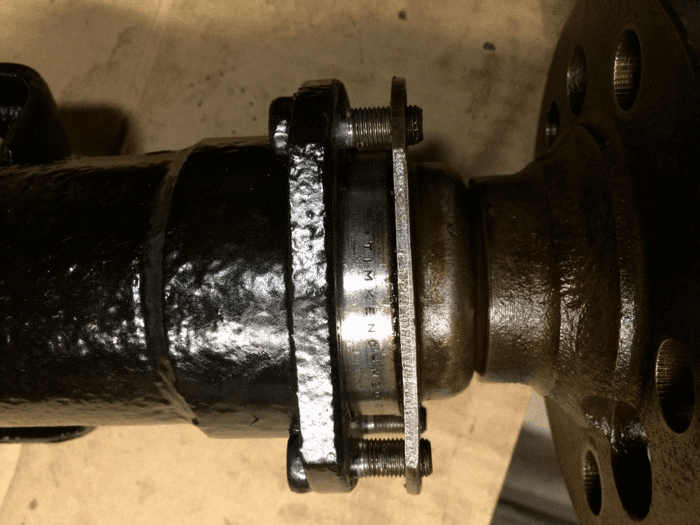

I'm having a problem trying to install/bench fit the left side (drivers side) 8 3/4 axle into a 742 center section. It's a project I'm finally getting to this summer after a number of years sitting in dry storage. Here's the story... A few years ago I purchased a used complete 8 3/4 rear end out of a 1973 Dodge Challenger. It was a complete 8 3/4 original axle assemble that had an open 489 case. I then found and purchased a used 742 center section with a clutch type Sure Grip with 3:23 gears. I removed the 489 center section and installed the 742 Sure Grip center section into the 8 3/4 axle housing. I'm now trying to install/bench fit the original axles into the 742 center section but have run into problems. The drivers side axle does not want to fully seat into the 742 center section. It sounds like the axle is bottoming out inside the 742 center section. The passengers side axle fits fine, no issues. Just for kicks, I purposely swapped axle shafts. The problem remains on the drivers side only. I inspected the 742 Sure Grip before installing into the 8 3/4 axle housing. The thrust button is there and I don't recall seeing any spline damage. I'm sure I'm missing something. There's a ton of information on these 8 3/4 axles but I don't recall seeing this problem. I think I read somewhere that possibly the axle has to be twisted/torqued to install fully seat into a clutch type Sure Grip? I don't know if there is any truth to that statement. Attached are a few pictures of what I'm dealing with.

Thanks in advance for your help,

Tirekickertoo

I'm having a problem trying to install/bench fit the left side (drivers side) 8 3/4 axle into a 742 center section. It's a project I'm finally getting to this summer after a number of years sitting in dry storage. Here's the story... A few years ago I purchased a used complete 8 3/4 rear end out of a 1973 Dodge Challenger. It was a complete 8 3/4 original axle assemble that had an open 489 case. I then found and purchased a used 742 center section with a clutch type Sure Grip with 3:23 gears. I removed the 489 center section and installed the 742 Sure Grip center section into the 8 3/4 axle housing. I'm now trying to install/bench fit the original axles into the 742 center section but have run into problems. The drivers side axle does not want to fully seat into the 742 center section. It sounds like the axle is bottoming out inside the 742 center section. The passengers side axle fits fine, no issues. Just for kicks, I purposely swapped axle shafts. The problem remains on the drivers side only. I inspected the 742 Sure Grip before installing into the 8 3/4 axle housing. The thrust button is there and I don't recall seeing any spline damage. I'm sure I'm missing something. There's a ton of information on these 8 3/4 axles but I don't recall seeing this problem. I think I read somewhere that possibly the axle has to be twisted/torqued to install fully seat into a clutch type Sure Grip? I don't know if there is any truth to that statement. Attached are a few pictures of what I'm dealing with.

Thanks in advance for your help,

Tirekickertoo