73Challengr

Member

- Joined

- Apr 3, 2020

- Messages

- 21

- Reaction score

- 14

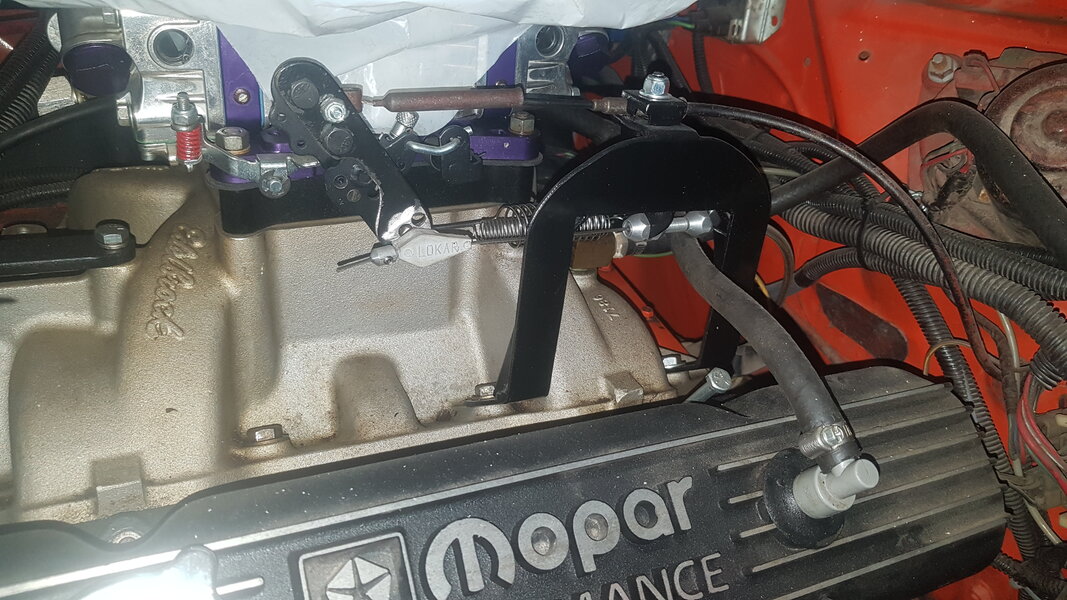

I've got a 73 Challeger i'm going to put a shift kit in (vendor recommendations welcome). It currently doesn't have a kickdown cable/linkage (vendor recommendations welcome). Will I need one? Thanks much!