You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

74 Challenger. No sheetmetal to be harmed and adding twins

- Thread starter 74chlngrTT5.9

- Start date

74chlngrTT5.9

Well-Known Member

They are from an Ebay retailer

T3/T4, .50 AR Compressor, .63 AR Turbine

I jumped into this project with both feet knowing next to nothing on the realistic sizing for them. As I am now farther into it I suspect they might be too small for my application and eventual HP goal. 500-550 crank. When building the headers I made sure the turbos were positioned with enough open real estate around them so if I needed to replace with larger frame units I can.

Also... If/when this concludes and the miles start racking up on the car, they will be replaced with better quality versions for longevity

Mike.

T3/T4, .50 AR Compressor, .63 AR Turbine

I jumped into this project with both feet knowing next to nothing on the realistic sizing for them. As I am now farther into it I suspect they might be too small for my application and eventual HP goal. 500-550 crank. When building the headers I made sure the turbos were positioned with enough open real estate around them so if I needed to replace with larger frame units I can.

Also... If/when this concludes and the miles start racking up on the car, they will be replaced with better quality versions for longevity

Mike.

Last edited:

74chlngrTT5.9

Well-Known Member

Well, the new job does get in the way of progress. Imagine that...

Small update:

Working on fuel system.

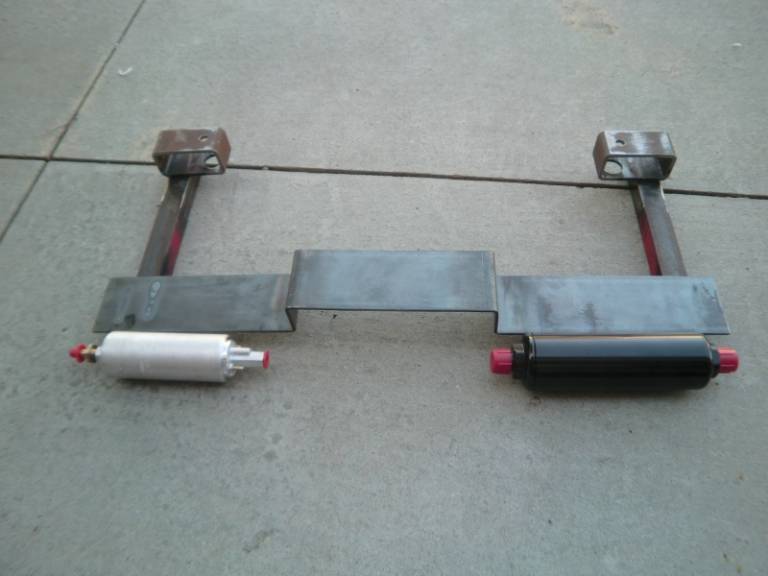

Made a bracket using scrap pieces.

It mounts to the cross member above the differential. The box tube is a spacer. The mounting surface is small hole side and large hole side is for access.

Bent strap is the horizontal bar pump and filter mounts on. It will hang down in between the gas tank and differential. Bend provides clearance for pumpkin.

Going to mount like this

Using some straps and dense foam as an insulator to hopfully keep the noise down.

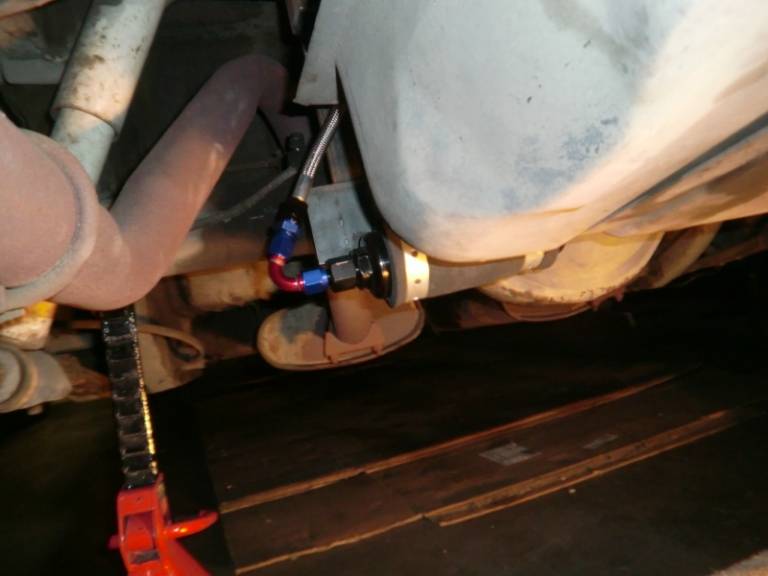

In true hot rod style, I bought a new sending unit and promptly started cutting it up.

Had to remove its wire contact and relocate it to make for room for the bulkhead.

Looks like a cluster fu~~ with all the fittings required to get to the pipe end but should work. I also removed the "sock" because I am using a pre-filter.

Shot from rear on left (drivers) side. Wanted to use all black fittings but supplier was out at the time. Completing the purchases trumped sticking with all black.

Pass side

Straight up from ground

What is visible looking from behind without crawling under.

Eventually it will be trimmed and cleaned up better and painted. Just aiming for functional now.

All flex lines are SS braided and Teflon lined ID so they should last and not permeate the fuel smell throughout my garage.

Ran some 14 and 16 gauge wire for the relays.

.

.

Mike.

Small update:

Working on fuel system.

Made a bracket using scrap pieces.

It mounts to the cross member above the differential. The box tube is a spacer. The mounting surface is small hole side and large hole side is for access.

Bent strap is the horizontal bar pump and filter mounts on. It will hang down in between the gas tank and differential. Bend provides clearance for pumpkin.

Going to mount like this

Using some straps and dense foam as an insulator to hopfully keep the noise down.

In true hot rod style, I bought a new sending unit and promptly started cutting it up.

Had to remove its wire contact and relocate it to make for room for the bulkhead.

Looks like a cluster fu~~ with all the fittings required to get to the pipe end but should work. I also removed the "sock" because I am using a pre-filter.

Shot from rear on left (drivers) side. Wanted to use all black fittings but supplier was out at the time. Completing the purchases trumped sticking with all black.

Pass side

Straight up from ground

What is visible looking from behind without crawling under.

Eventually it will be trimmed and cleaned up better and painted. Just aiming for functional now.

All flex lines are SS braided and Teflon lined ID so they should last and not permeate the fuel smell throughout my garage.

Ran some 14 and 16 gauge wire for the relays.

Mike.

Last edited:

AZkcar135

Active Member

There was an article in one of the Mopar magazines awhile back where a guy threw a couple of turbos of the 4 cyl turbo dodges and he had to bypass some of the exhaust past the turbos. The garrett turbos where the bigger and only needed 2.2-2.5 ltrs to spool up.

74chlngrTT5.9

Well-Known Member

Prior to purchasing these, I JY shopped a lot and looked over many different ones from the Dodges you mentioned along with some Volvo and also Saab units. Of the 3, the Volvo one had the largest wheels. The ones with the 5 cylinder motors not the older 4 cylinders. Never physically measured them though. Was told that these knock offs I purchased should be reasonably correct for my setup. Not planning on going for the gold...

The current locations (when finally installed) are such that if I do need to go larger there is room for it without revamping everything. I am sure when this gets closer to fruition I will start actually studying some maps for a better understanding of my requirements.

Mike

The current locations (when finally installed) are such that if I do need to go larger there is room for it without revamping everything. I am sure when this gets closer to fruition I will start actually studying some maps for a better understanding of my requirements.

Mike

AZkcar135

Active Member

The 2.2 intercooler turbo are pretty big. Bigger than any volvo turbo.

moparleo

Well-Known Member

- Joined

- Oct 17, 2011

- Messages

- 7,265

- Reaction score

- 2,061

Looking good Mike.

74chlngrTT5.9

Well-Known Member

Still plugging away with very little time because of the now not so new job.

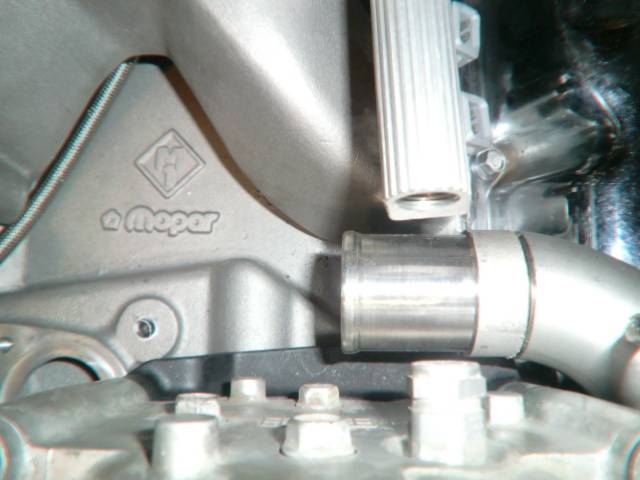

Currently installing/adapting the Magnum front accessories on the 360la

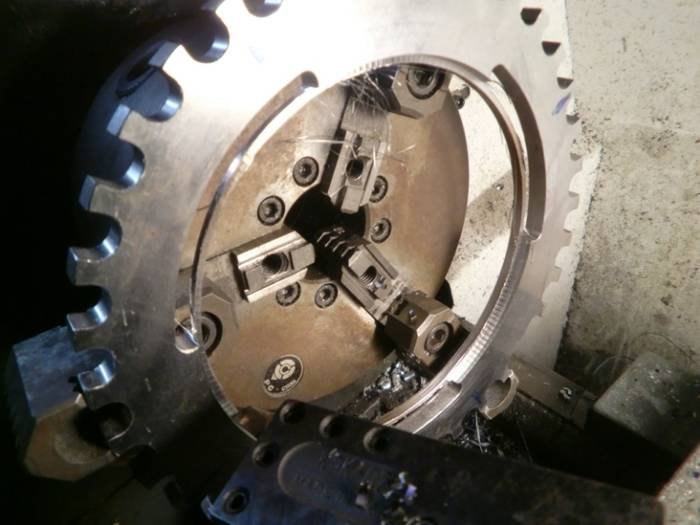

The bold on crank trigger wheel setup made for the Magnum would not work on the old motor. The old 360 crank counter weight is much larger and sticks out farther so it interfered with my modified lower belt pulley. So off it comes and back into the lathe it goes.

I turned off all of the mounting slots to increase it's ID and will just weld it on to the pulley and will end up making a bracket to hold the sensor with ample adjustment.

Not mounted yet but will just be on the inner side of lower pulley.

Now on to the engine side. Started with the tear down to add the Magnum accessories.

Used the gaskets as templates and started to drill out the intake for the old style mounting.

Kept trying to figure out how to drill all them precise enough on my mill. Tried to set up sign plate and angle brackets but all ways turned into too tall of setups to work on a mill. Went old school and made a simple drill fixture and drilled them by hand.

Holes appeared to be somewhere around 7 degrees off of perpendicular.

Drilled a guide block.

Welded it to a strap that I clamp to the mounting face and out comes the cordless.

I used dykem and colored the surface, located the gasket and scribed the location. Looked down the hole and went to town.

I will turn up some thick washers with cutouts to clear the partial post that is in the way.

Bolted on the timing cover and as believed it fit correctly. It is still deep enough to allow me to not remove the mechanical fuel pump cam eccentric.

The made and then modified P/S pump bracket bolted up correctly and the hoses will clear everything.

A problem for this conversion is on the passenger side withe the tensioner. old motor doesn't have the same mounting points for the tensioner. The lower one is in same location but is farther back so I used spacers to pull it out.

Welded on a mounting tab that aligns up with the heads two upper bolt holes. The lower 3rd one is in correct location but too far back so I added some spacers.

Turned out kind of ugly but simple and functional.

Milled off some of the main bracket to allow the new piece to fit in.

Upper one is the original one I modified the slot to allow the wheel to rotate slightly inward for turbo clearance. Newly modded one I rotated the whole bracket inward from the lower bolt to accomplish the same thing. I will have still have the same factory tension because the relocated P/S pump took up more belt length.

Top view with new shorter accessories and miles of room for the goodies.

Front shot. Would be close if I still had the flat hood.

Of course had to hang the turbos on there again for the visual.

Mockup money shot.

Top view showing the room remaining for the twin electric fans and cold piping. I had to switch out radiators because the lower hose on the original one interfered with the front of the torsion bar bolt when it was moved off of the core support. Got lucky with the lower hose. Turns out I was able to use a factory formed one that matches my Dak R/T.

Next up on the bucket list is to remove the turbos again :-(

2) Finish the fuel delivery setup

3) Modify the fuel rails so the carburetor linkage doesn't interfere.

4) Finish the fan an pump wiring.

5) Drive it N/A again this summer and hopefully get it converted to EFI.

Mike.

Currently installing/adapting the Magnum front accessories on the 360la

The bold on crank trigger wheel setup made for the Magnum would not work on the old motor. The old 360 crank counter weight is much larger and sticks out farther so it interfered with my modified lower belt pulley. So off it comes and back into the lathe it goes.

I turned off all of the mounting slots to increase it's ID and will just weld it on to the pulley and will end up making a bracket to hold the sensor with ample adjustment.

Not mounted yet but will just be on the inner side of lower pulley.

Now on to the engine side. Started with the tear down to add the Magnum accessories.

Used the gaskets as templates and started to drill out the intake for the old style mounting.

Kept trying to figure out how to drill all them precise enough on my mill. Tried to set up sign plate and angle brackets but all ways turned into too tall of setups to work on a mill. Went old school and made a simple drill fixture and drilled them by hand.

Holes appeared to be somewhere around 7 degrees off of perpendicular.

Drilled a guide block.

Welded it to a strap that I clamp to the mounting face and out comes the cordless.

I used dykem and colored the surface, located the gasket and scribed the location. Looked down the hole and went to town.

I will turn up some thick washers with cutouts to clear the partial post that is in the way.

Bolted on the timing cover and as believed it fit correctly. It is still deep enough to allow me to not remove the mechanical fuel pump cam eccentric.

The made and then modified P/S pump bracket bolted up correctly and the hoses will clear everything.

A problem for this conversion is on the passenger side withe the tensioner. old motor doesn't have the same mounting points for the tensioner. The lower one is in same location but is farther back so I used spacers to pull it out.

Welded on a mounting tab that aligns up with the heads two upper bolt holes. The lower 3rd one is in correct location but too far back so I added some spacers.

Turned out kind of ugly but simple and functional.

Milled off some of the main bracket to allow the new piece to fit in.

Upper one is the original one I modified the slot to allow the wheel to rotate slightly inward for turbo clearance. Newly modded one I rotated the whole bracket inward from the lower bolt to accomplish the same thing. I will have still have the same factory tension because the relocated P/S pump took up more belt length.

Top view with new shorter accessories and miles of room for the goodies.

Front shot. Would be close if I still had the flat hood.

Of course had to hang the turbos on there again for the visual.

Mockup money shot.

Top view showing the room remaining for the twin electric fans and cold piping. I had to switch out radiators because the lower hose on the original one interfered with the front of the torsion bar bolt when it was moved off of the core support. Got lucky with the lower hose. Turns out I was able to use a factory formed one that matches my Dak R/T.

Next up on the bucket list is to remove the turbos again :-(

2) Finish the fuel delivery setup

3) Modify the fuel rails so the carburetor linkage doesn't interfere.

4) Finish the fan an pump wiring.

5) Drive it N/A again this summer and hopefully get it converted to EFI.

Mike.

03HDFB

Well-Known Member

- Joined

- Oct 17, 2013

- Messages

- 209

- Reaction score

- 21

Nice Work....Been follwing this post for awhile now!

G

G

quapman

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 878

- Reaction score

- 227

Wow. You've got some serious skills. I give you huge kudos for having the patience to go from full-blown CNC to a Bridgeport to do so much of this work.

What exactly do you do for your "real" job? Engineer? Toolmaker? Fabricator?

I feel your pain on the family-owned deal. I went through that around 2001.

If I had more time, I'd offer to finish your hood emblems for you. I recently purchased my own VMC and know Mastercam well. Not to mention, I'd be deathly afraid of fat-fingering a number and f-ing up your hard work. You must have spent some time just creating the CAD file for those.

What exactly do you do for your "real" job? Engineer? Toolmaker? Fabricator?

I feel your pain on the family-owned deal. I went through that around 2001.

If I had more time, I'd offer to finish your hood emblems for you. I recently purchased my own VMC and know Mastercam well. Not to mention, I'd be deathly afraid of fat-fingering a number and f-ing up your hard work. You must have spent some time just creating the CAD file for those.

ramenth

Well-Known Member

Mike, that is some fantastic fab work!

74chlngrTT5.9

Well-Known Member

Wow. You've got some serious skills. I give you huge kudos for having the patience to go from full-blown CNC to a Bridgeport to do so much of this work.

What exactly do you do for your "real" job? Engineer? Toolmaker? Fabricator?

I feel your pain on the family-owned deal. I went through that around 2001.

If I had more time, I'd offer to finish your hood emblems for you. I recently purchased my own VMC and know Mastercam well. Not to mention, I'd be deathly afraid of fat-fingering a number and f-ing up your hard work. You must have spent some time just creating the CAD file for those.

Sorry for the delayed response. Haven't logged in recently.

In general I am a machinist that specializes in producing plastic injection molds.

Started programming with Mastercam way back when on an old computer with a 286 processor.

Thru the years migrated to ProEngineer 3D modeling doing the product and injection mold designing and eventually they switched over to Solidworks. Digressed a bit when the shop went from building them to having tools built in China. I then became the project manager and offshore contact. Also managed the tool room for the repairs so I was still programming and running their Haas machines.

Too much continuously on my plate. Hence the change.

And to answer your initial comment, yes all manual now has had it's frustrating moments but it is for me now so there is no room for excuses. lol.

74chlngrTT5.9

Well-Known Member

Project update time.

Was initially going to go with only a few items so I could get it together again and attend the Mopar Spring Thing but as I am sure many out there know from experience that everything takes longer than expected...

I did not want to have to tear into it again backtracking where I was already so I decided to go in deeper.

Made some simple brackets to mount the dual JY fan setup.

Hangs over the top

Locks in from the bottom. After the pic I bent out the lower brackets slightly so they are no longer in contact with the cooling tube.

Added some clearances for the hoses

With the addition of the electric fans comes more wiring.

I am going to utilize and modify a power fuse box from a Ford. It has 4 relay and 2 rows of large and small fuses. Chose this one because of it's size and also it can easily be modified so some of the fuses/relays are always powered (IE cooling fans) and some only on while switched.

The box. Ford will get wiped off the lid.

Pulled all the pins so I can customize it.

Sticking with my theme as best as possible. I am making a mounting plate that mounts with existing holes in the fender.

It has 2 extra surfaces that extend outward from the box that I can relocate and mount the factory relays that already exist over there. It sits up higher than I really like but is required for the exhaust piping clearance. During the mock up I used some modeling clay on it's top and closed the hood to check for clearances. There is about 1/2 inch when the lid is on.

Not really what I want aesthetically but it is a much lower cost alternative I can live with. It will neatly tie up all the additional wiring that will be going in it.

Since all the front accessory items are off, I decided to drop the oil pan and add my drain bungs.

I had read that the pan can be dropped with the simple removal of the suspension cross link. Not on my car... The pan hits the motor mount brackets. So off they go.

I made a mini frame that sits on the car frame. It uses a piece of all thread and a couple of nuts and a big a$$ pair of channel locks to draw it up. Works good.

.

.

From my earlier visions of using JY turbos I also picked up their factory drain pipes. Hacked them off short and welded them on. The black "spray" seen in the pics is not from the welding. It is paint. Way back when I had the motor painted yellow to match the car but ended up not liking it so I repainted as much as I could reach and see black.

I am now officially in the reassembly stage.

Going to try and see if I can live with solid motor mounts.

TC and all front mounted items are fit. Just some cleaning and painting required before final mounting.

Then finish drilling the intake and make the custom washers to mount it.

Finish fuel system after that.

Mike

Was initially going to go with only a few items so I could get it together again and attend the Mopar Spring Thing but as I am sure many out there know from experience that everything takes longer than expected...

I did not want to have to tear into it again backtracking where I was already so I decided to go in deeper.

Made some simple brackets to mount the dual JY fan setup.

Hangs over the top

Locks in from the bottom. After the pic I bent out the lower brackets slightly so they are no longer in contact with the cooling tube.

Added some clearances for the hoses

With the addition of the electric fans comes more wiring.

I am going to utilize and modify a power fuse box from a Ford. It has 4 relay and 2 rows of large and small fuses. Chose this one because of it's size and also it can easily be modified so some of the fuses/relays are always powered (IE cooling fans) and some only on while switched.

The box. Ford will get wiped off the lid.

Pulled all the pins so I can customize it.

Sticking with my theme as best as possible. I am making a mounting plate that mounts with existing holes in the fender.

It has 2 extra surfaces that extend outward from the box that I can relocate and mount the factory relays that already exist over there. It sits up higher than I really like but is required for the exhaust piping clearance. During the mock up I used some modeling clay on it's top and closed the hood to check for clearances. There is about 1/2 inch when the lid is on.

Not really what I want aesthetically but it is a much lower cost alternative I can live with. It will neatly tie up all the additional wiring that will be going in it.

Since all the front accessory items are off, I decided to drop the oil pan and add my drain bungs.

I had read that the pan can be dropped with the simple removal of the suspension cross link. Not on my car... The pan hits the motor mount brackets. So off they go.

I made a mini frame that sits on the car frame. It uses a piece of all thread and a couple of nuts and a big a$$ pair of channel locks to draw it up. Works good.

From my earlier visions of using JY turbos I also picked up their factory drain pipes. Hacked them off short and welded them on. The black "spray" seen in the pics is not from the welding. It is paint. Way back when I had the motor painted yellow to match the car but ended up not liking it so I repainted as much as I could reach and see black.

I am now officially in the reassembly stage.

Going to try and see if I can live with solid motor mounts.

TC and all front mounted items are fit. Just some cleaning and painting required before final mounting.

Then finish drilling the intake and make the custom washers to mount it.

Finish fuel system after that.

Mike

Last edited:

74chlngrTT5.9

Well-Known Member

Been buttoning up the details.

Got the manifolds and exhaust back on.

Oil pan is painted and on.

Solid mounts are on.

Finished drilling my intake. It was a tedious pain in the backside drilling it by hand.

Will be doing some port matching

Since I will not be using the Magnum mounting, I threaded the post holes so I can use them as mounting points for the throttle cable bracket and also (yet to be made) brackets to hold in the injectors.

Top view of front and rear "new" holes.

Half the set of spacer washers.

Mock up of how the space and bolt will look like "as mounted".

Mike.

Got the manifolds and exhaust back on.

Oil pan is painted and on.

Solid mounts are on.

Finished drilling my intake. It was a tedious pain in the backside drilling it by hand.

Will be doing some port matching

Since I will not be using the Magnum mounting, I threaded the post holes so I can use them as mounting points for the throttle cable bracket and also (yet to be made) brackets to hold in the injectors.

Top view of front and rear "new" holes.

Half the set of spacer washers.

Mock up of how the space and bolt will look like "as mounted".

Mike.

mmissile

Well-Known Member

Seriously cool fabbing.

74chlngrTT5.9

Well-Known Member

The intake ports have been gasket matched.

One done and one as cast to show the difference. Heads have previously been matched years ago.

Done. It doesn't look like it in the pics but the blend is tapered fairly far into the ports.

Also had to mill .06/.07 off of the upper port wall to eliminate interference with the valve covers.

Also made some progress on the hybrid carb/FI manifold setup.

Carburetor linkage interference has been causing a lot of grief. To help I will be using a spacer to lift it up

approximately 5/8.

It started life long ago at 3/4 but was beat up and warped so I milled it flat again.

Even with the spacer, the FI fuel logs would not fit as a solid bar for each bank. I cut the center portion out,

drilled and tapped a 30 deg angled connection on the bottom of them. The inner ends will then just get plugged.

The "mini" rails on each bank will be connected with a looped down hose. Hope this doesn't end up causing an air

trap issue.

Rail pieces

Mounting brackets that will bolt to the original vertical mounting holes I tapped.

Mockup set on engine showing brackets. You can also see the middle section lower loop hose.

Fuel "fill" line will run under manifold ports and "Y" to the front of the bars. Carburetor line "fill" is in the

back and the drain comes out the front and will return towards the back.

Regulator in the rear. Due to space issues I am going to try to hard plumb the EFI return lines.

All the EFI plumbing will not be connected when the carburetor is used at the start.

All this has been like trying to stuff 10lb of crap in a 5lb bag.

But is finally getting close to being officially bolted on.

Also picked up a set of coils for the eventual conversion.

The upper radiator hose will be running behind the air pump instead of over as the factory did so I angle cut and have tacked it together for testing.

Seems like that once you change one thing everything ends up having to change.

I WANT TO DRIVE THIS THING ALREADY...

Mike.

One done and one as cast to show the difference. Heads have previously been matched years ago.

Done. It doesn't look like it in the pics but the blend is tapered fairly far into the ports.

Also had to mill .06/.07 off of the upper port wall to eliminate interference with the valve covers.

Also made some progress on the hybrid carb/FI manifold setup.

Carburetor linkage interference has been causing a lot of grief. To help I will be using a spacer to lift it up

approximately 5/8.

It started life long ago at 3/4 but was beat up and warped so I milled it flat again.

Even with the spacer, the FI fuel logs would not fit as a solid bar for each bank. I cut the center portion out,

drilled and tapped a 30 deg angled connection on the bottom of them. The inner ends will then just get plugged.

The "mini" rails on each bank will be connected with a looped down hose. Hope this doesn't end up causing an air

trap issue.

Rail pieces

Mounting brackets that will bolt to the original vertical mounting holes I tapped.

Mockup set on engine showing brackets. You can also see the middle section lower loop hose.

Fuel "fill" line will run under manifold ports and "Y" to the front of the bars. Carburetor line "fill" is in the

back and the drain comes out the front and will return towards the back.

Regulator in the rear. Due to space issues I am going to try to hard plumb the EFI return lines.

All the EFI plumbing will not be connected when the carburetor is used at the start.

All this has been like trying to stuff 10lb of crap in a 5lb bag.

But is finally getting close to being officially bolted on.

Also picked up a set of coils for the eventual conversion.

The upper radiator hose will be running behind the air pump instead of over as the factory did so I angle cut and have tacked it together for testing.

Seems like that once you change one thing everything ends up having to change.

I WANT TO DRIVE THIS THING ALREADY...

Mike.

74chlngrTT5.9

Well-Known Member

Finally have something to show again. It's been slow going.

Finished blending the intake ports and got it mounted.

Mounted the front accessories.

It seems that no matter how many times you mock up things it isn't enough. One small thing pops up and bites you.

When bolting on the upper alt and air pump bracket it just didn't feel right when tightening the bolts. Decided to take it back off to investigate. Good thing because it was stuck even unbolted. Had to pry it off because it was wedged onto one of the new manifold mounting bolts. Easy fix, so out comes the disc sander.

Good thing I stopped. It probably would of cracked the bracket.

Always trying to think ahead. While there was room I Drilled and tapped the front P/S housing plate in 2 places for a crank trigger switch bracket (yet to be made).

Starting mock up for the throttle cable mounting bracket

All the injector fuel log brackets are made and painted. Had to mod the rails again slightly to add more clearance around the angled fittings. When tightening them on I couldn't get a wrench on them.

This is how I want to mount the regulator. Rails fill in the front and out the rear. Might have to make a dummy NPT adapter or hopefully I can plug the inside of this one while the carburetor is being used so there isn't gas going into the rail system and sitting there getting stagnant.

Radiator temporarily hung in place again as I move on to some of the fuse block and relay wiring.

One dilemma I am pondering is the intercoolers. They are almost complete on their mockup and a lot of their welding is complete but...

As I have completed 100% of all items that have been documented thus far on this build, I want that to continue but I also want this to move forward. I am considering paying someone to finish welding them up so when I assemble this time I will not have to remove everything again when adding the turbos. We'll see soon if my cheep wins out or project progression. lol

Mike.

Finished blending the intake ports and got it mounted.

Mounted the front accessories.

It seems that no matter how many times you mock up things it isn't enough. One small thing pops up and bites you.

When bolting on the upper alt and air pump bracket it just didn't feel right when tightening the bolts. Decided to take it back off to investigate. Good thing because it was stuck even unbolted. Had to pry it off because it was wedged onto one of the new manifold mounting bolts. Easy fix, so out comes the disc sander.

Good thing I stopped. It probably would of cracked the bracket.

Always trying to think ahead. While there was room I Drilled and tapped the front P/S housing plate in 2 places for a crank trigger switch bracket (yet to be made).

Starting mock up for the throttle cable mounting bracket

All the injector fuel log brackets are made and painted. Had to mod the rails again slightly to add more clearance around the angled fittings. When tightening them on I couldn't get a wrench on them.

This is how I want to mount the regulator. Rails fill in the front and out the rear. Might have to make a dummy NPT adapter or hopefully I can plug the inside of this one while the carburetor is being used so there isn't gas going into the rail system and sitting there getting stagnant.

Radiator temporarily hung in place again as I move on to some of the fuse block and relay wiring.

One dilemma I am pondering is the intercoolers. They are almost complete on their mockup and a lot of their welding is complete but...

As I have completed 100% of all items that have been documented thus far on this build, I want that to continue but I also want this to move forward. I am considering paying someone to finish welding them up so when I assemble this time I will not have to remove everything again when adding the turbos. We'll see soon if my cheep wins out or project progression. lol

Mike.

74chlngrTT5.9

Well-Known Member

Finished the throttle cable mount. Nothing elaborate, a simple plate with the factory clamp welded on.

This is only temporary prior to the EFI conversion.

Got the Hydroboost lines buttoned up. Don't really like the way the fittings look but on to more pressing items.

Again was trying to go cheap and simple with the upper radiator hose but didn't like how it was looking and working out.

Started with this

Got some stainless pipe and turned the ends down to be proper for the 1.5 dia. hose ends.

Along with some bends, I fired up the welder.

Made a flange and this is my new housing.

Snaked the other half through and around. Initially I was going to have hose go over the fuel rail but it was too high. Higher than the radiator fill. This would cause an air trap issue. Had to also make a different fuel rail mounting bracket for the front one to open up the area for the hose to pass through.

All welded

SS = soft

Concrete = hard

Fixed the dent, ground and sanded them smooth. Not polished just smooth.

My first iteration was several hose pieces with aluminum straights and bends.

This is much nicer looking.

Mike.

This is only temporary prior to the EFI conversion.

Got the Hydroboost lines buttoned up. Don't really like the way the fittings look but on to more pressing items.

Again was trying to go cheap and simple with the upper radiator hose but didn't like how it was looking and working out.

Started with this

Got some stainless pipe and turned the ends down to be proper for the 1.5 dia. hose ends.

Along with some bends, I fired up the welder.

Made a flange and this is my new housing.

Snaked the other half through and around. Initially I was going to have hose go over the fuel rail but it was too high. Higher than the radiator fill. This would cause an air trap issue. Had to also make a different fuel rail mounting bracket for the front one to open up the area for the hose to pass through.

All welded

SS = soft

Concrete = hard

Fixed the dent, ground and sanded them smooth. Not polished just smooth.

My first iteration was several hose pieces with aluminum straights and bends.

This is much nicer looking.

Mike.

moparleo

Well-Known Member

- Joined

- Oct 17, 2011

- Messages

- 7,265

- Reaction score

- 2,061

Sometimes it is whatever works.

74chlngrTT5.9

Well-Known Member

Was able to plug the inside of the NPT coupler temporarily so the rails will not fill with gas while carburated.

Luckily I remembered to check flatness.

.

.

And now milled to correct.

Previously stated this will be power distribution block location but could not get past hating the location.

So it will now be located here instead. It is only resting there. It actually fits in this location perfectly and will mount lower so it is flush.

Ford. Now you see it.

Now you don't LOL...

Placing the box here will require additional wiring relocation mods for the starter relay and seat belt switch. I will use jumpers to extend them and also add a power connection block for the battery, starter, alternator wires and fuse block. This revised setup will allow the wiring to be run down low by the frame rail and mostly out of sight. Still in the EARLY stages of change.

Made a mounting plate that will mount down low and to the drivers side radiator bracket.

Found some connectors that are the same size/style as factory pieces. They even have the same outer plastic covering.

Jumpers installed in factory plug.

Mike.

Luckily I remembered to check flatness.

And now milled to correct.

Previously stated this will be power distribution block location but could not get past hating the location.

So it will now be located here instead. It is only resting there. It actually fits in this location perfectly and will mount lower so it is flush.

Ford. Now you see it.

Now you don't LOL...

Placing the box here will require additional wiring relocation mods for the starter relay and seat belt switch. I will use jumpers to extend them and also add a power connection block for the battery, starter, alternator wires and fuse block. This revised setup will allow the wiring to be run down low by the frame rail and mostly out of sight. Still in the EARLY stages of change.

Made a mounting plate that will mount down low and to the drivers side radiator bracket.

Found some connectors that are the same size/style as factory pieces. They even have the same outer plastic covering.

Jumpers installed in factory plug.

Mike.

Last edited: