I will show what is going on in the E body ammeter circuitry and the frailties. Much of the advice above is good.

There are several underlying reasons you need to be concerned about the E body charging circuit and ammeter wiring:

- the harness design for the E body originates on the engineering boards for B bodies about 7 years before the Challenger debuts

- the design features "in-harness" ties for battery, accessory, and ignition. Bear in mind these ties are soldered, tape wrapped and placed inline within the harness.

- the Packard 56 terminals are just that, terminals from 1956

- the ammeter circuit measures the current between the battery tie and alternator output. Period. Saying current only flows when this or that is happening =NOT. The ammeter registers a discharge when the battery is discharging or a charge when the alternator is charging the battery. The total current draw/supply is running through the ammeter!

Referring to below we are talking about R6-12BK and A1-12R. R6-12BK originates on port 18 of the bulkhead. Goes to the battery tie and on to the ammeter. Horn, headlights and the fuse panel battery side are also on this R6-12BK circuit. What protects them? We have to go to the engine harness side of the circuit.

Also note A1-12R is coming to the ammeter from port 16 of the bulkhead.

On the engine harness side we see port 18 is fed directly from the alternator battery output. Port 16 connects to the battery positive through a fusible link. This link is the only protection on the wiring from the loads on the other side. Again, the ammeter is in the charge path between the alternator and battery. It "sees" both discharge and charge, all current to & from the battery passes through. Note an ammeter senses current flow without a ground. The circuit load itself is moving current (electrons) from positive to negative (ground) - the ammeter is sensing the (via a field) the current passing. A shunt "shunts" some of the current away from the ammeter and allows it to effectively read higher loads.

Now for the evidence. Look at the 18 port on this bulkhead. This is from a 35 amp alternator! The wiring was in good shape. The connections had been cleaned and mated with dielectric grease.

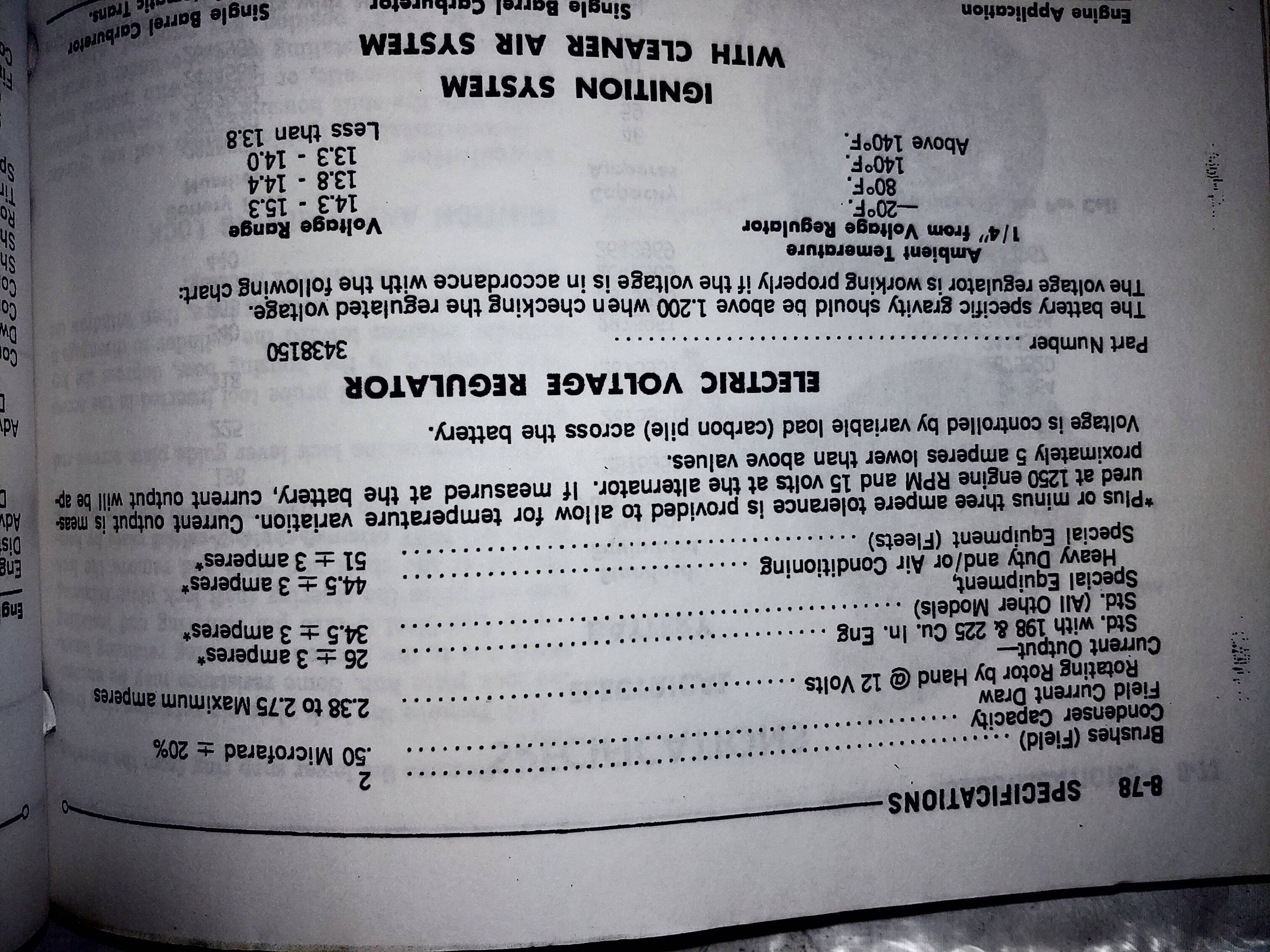

Here's the technical. The ampacity of wire - and we are talking about 12 gauge on this circuit here - is related to temperature and the wire's cross-section. 12volts DC has an ampacity table that's very easy to look up. The table's usually take a temperature limit of the wire plus some safety factory to rate the wire ampacity. In rough numbers at 12vdc/10 amps a 12 gauge wire is rated at about 15 feet. What you say? An E body alternator circuit must have about 15 feet of wire between the runs to the ammeter and back to the start relay. 10 amps. So as RTA above says the circuit isnt handling much current most of the time; a little charge, a little discharge. Until a short or other load comes along. Then its too late.. Running the headlights in low alternator output discharging the battery puts all this current drain through the ammeter and bulkhead to the battery tie. Things can get warm just with that load. Now deep discharge the battery so that on next startup the voltage regulator sees a low battery and juices the field and charge current to the max. Moparroy above correctly notes this case. Now we are getting hot. You see this fail isn't about a little current being sensed in normal operation.

What does a fuse in a circuit protect - the device or the wiring? If you said the device you misunderstand circuit design. The fuse protects the wiring always. At the device you can have another fuse to protect the device (like large audio power amps do) but that is separate. The E body circuit design is short on wiring protection.

BTW, a note on insulation. Mopar vintage wiring and cheap parts store PVC insulated wire has no place on your precious ride. Try a simple test. Take a piece of stock Mopar harness wire and a piece of new GXL or TXL wire. Put shrink tube on both, heat gun on high, and proceed to shrink both. The vintage or cheap wire will first bubble, then gas, then burn. The new cross-linked wire will tolerate multiples of heat the vintage wire does, and resist burning.

So what is the fix? Mentioned above it is pretty simple. There is no need for an ammeter in modern auto electrics. [There is an inductive ammeter you can use if you have a really sensitive load you want to run against a fixed battery ampere-hour budget, but in modern auto electrics the voltmeter tells us all we need to know about charging (13.7 -14.1v) and low battery (<12.1v) conditions.]

The Mopar ammeter bypass (short version):

- remove both battery tie and alternator charge leads from the engine harness bulkhead ports. Route A1-12R lead through an open firewall grommet to its companion on fuse block side. (Speedo cable grommet can be swapped to get more through the hole.) Leave port 18 inside wire to power fuse block.

- add fusible link or circuit breaker to alternator output and tie to start relay post common with battery.

- remove ammeter leads and bolt (1/4-20) the 2 ammeter leads together and tape off well.

The alternator charge path is now direct to the battery and protected. The battery tie R6-12BK is fed through the bound ammeter leads.

Any alternator upgrade deserves a total rethink of your electrical system. If you are running a big alternator on a stock harness you have been forewarned. I run a TuffStuff 150 amp 3 wire. 6 gauge charge wire. Common battery post in firewall. Trunk mounted battery. #1 positive and ground bus front to rear.

I'm also experienced in total rewires and Infinitybox CANBUS + PWM power control installs if anyone is interested.

-Bill