TomIGo

Well-Known Member

I have finally been getting some time into the 70 Challenger. Here is how the starting point looked. It is numbers matching everywhere. Was FY4, I was not able to find out when it was repainted. Was able to scratch areas of all sheet metal and the FY4 shows underneath everywhere except the passenger side quarter, so appears all the rest of the sheet metal is original!

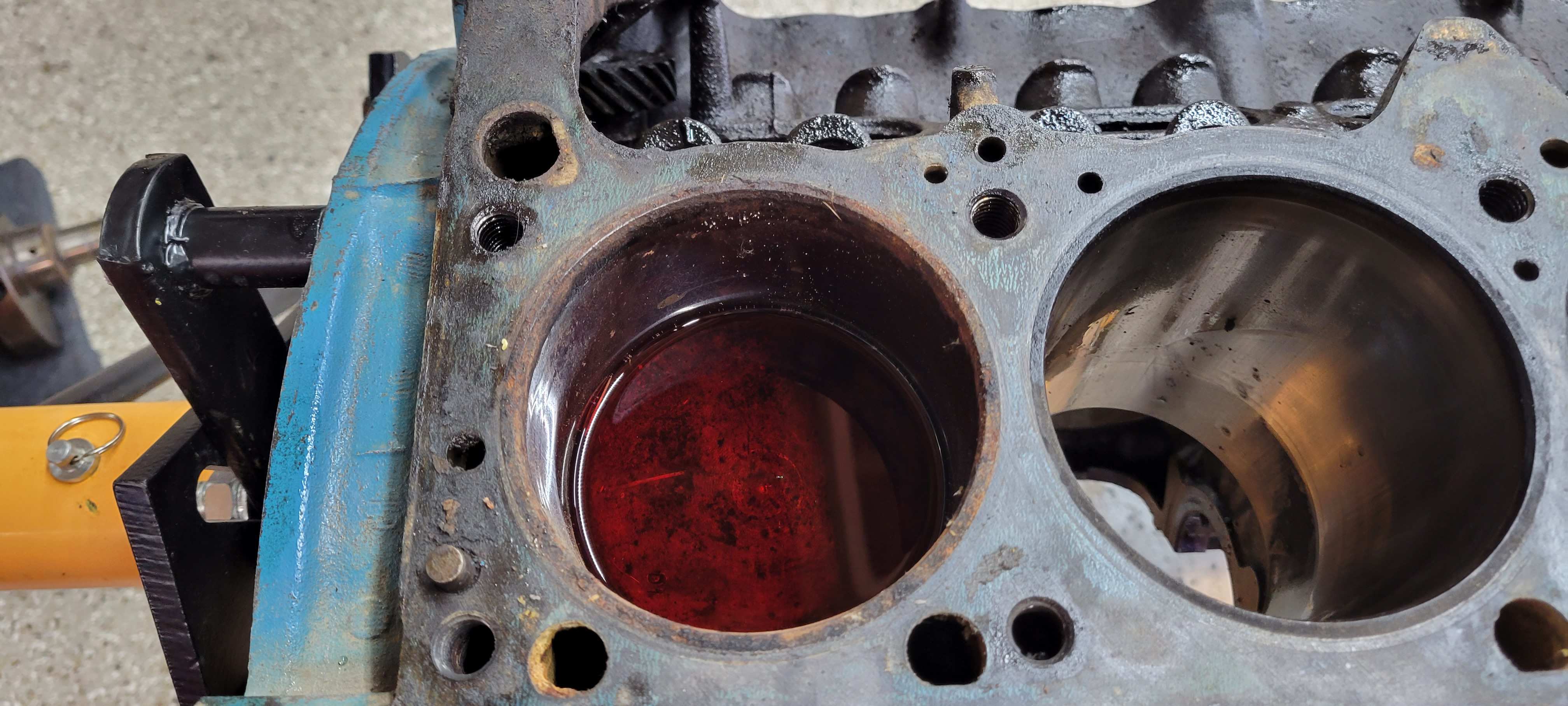

So far have removed the engine and trans and was able to free up a frozen cylinder enough to get all the parts out of the engine! Everything mechanical from the block looks ok except for cylinder number 8 that had a collapsed intake lifter and the piston rusted in place about half-way down the cylinder. Next up for that is measuring all the cylinders to see if it needs to be bored, or if I can get by with a good honing. Just by eye, the bad cylinder doesn't look too terribly scraped.

Also have the front of the car torn down to the frame rails and core support. The LH inside fender needs replacing as well as the shock mount, and some work is needed on the RH inner fender where the hood hinge attaches. I have removed as much rust as possible - I was surprised how much of it was just surface rust, and how nice the frame rails looked! All remaining was covered with a rust converter.

Interior is gutted except for the headliner, rear seat belts and dash. All will be coming out this weekend. Passenger side is covered in surface rust, but pounding on it with a screwdriver did no damage. Drivers floor is gone as well as part of the torsion bar support, so I am looking at a drivers side floor pan and a new support. I think Dynacorn has a full floor with everything, so I don't know maybe we'll do it all! The rear under seat pan is also no good, so that will be replaced.

Not planning on doing exterior panels at this time although they need lots of love. I already have 2 replacement fenders ready when I get to that point.

So far have removed the engine and trans and was able to free up a frozen cylinder enough to get all the parts out of the engine! Everything mechanical from the block looks ok except for cylinder number 8 that had a collapsed intake lifter and the piston rusted in place about half-way down the cylinder. Next up for that is measuring all the cylinders to see if it needs to be bored, or if I can get by with a good honing. Just by eye, the bad cylinder doesn't look too terribly scraped.

Also have the front of the car torn down to the frame rails and core support. The LH inside fender needs replacing as well as the shock mount, and some work is needed on the RH inner fender where the hood hinge attaches. I have removed as much rust as possible - I was surprised how much of it was just surface rust, and how nice the frame rails looked! All remaining was covered with a rust converter.

Interior is gutted except for the headliner, rear seat belts and dash. All will be coming out this weekend. Passenger side is covered in surface rust, but pounding on it with a screwdriver did no damage. Drivers floor is gone as well as part of the torsion bar support, so I am looking at a drivers side floor pan and a new support. I think Dynacorn has a full floor with everything, so I don't know maybe we'll do it all! The rear under seat pan is also no good, so that will be replaced.

Not planning on doing exterior panels at this time although they need lots of love. I already have 2 replacement fenders ready when I get to that point.

to FEBO from New Jersey

to FEBO from New Jersey