sdcbowler

Well-Known Member

- Joined

- Jun 4, 2015

- Messages

- 161

- Reaction score

- 38

Where to start.......

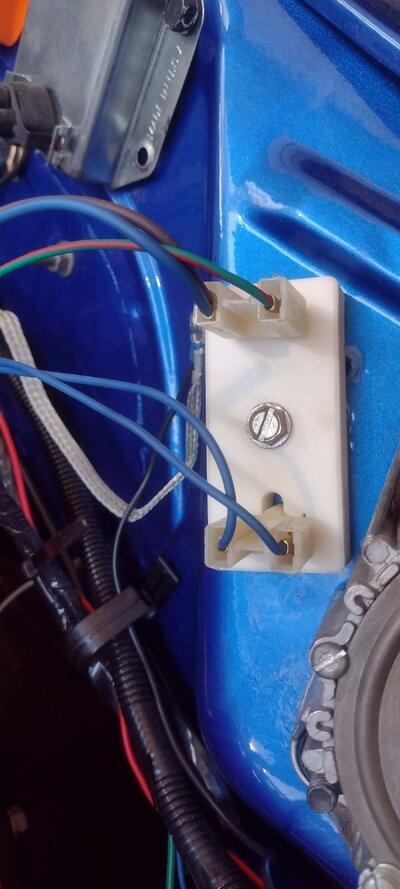

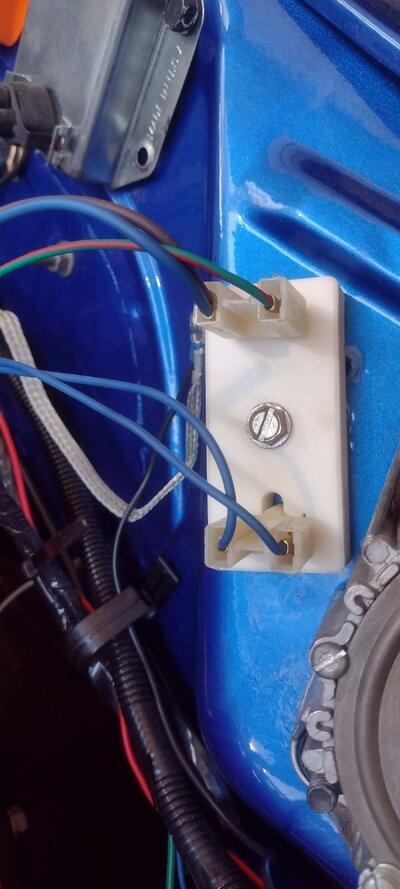

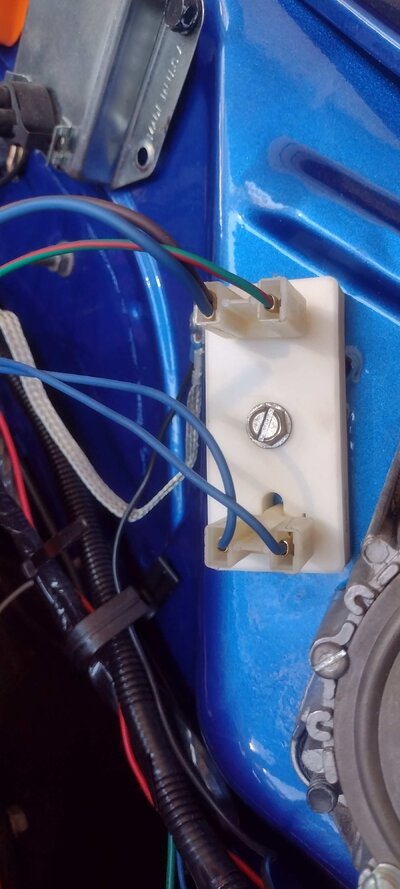

The first start-up of the day, with the e-choke engaged is ok. After the car heats up, is when the problems start. I have to use the fast idle cam to get it running. If I try to push the throttlle, the engine dies immediately. I haven't been able to set the timing because I can't even see the timing marks. The car has electronic ignition. Now, my aftermarket harness is for an E.I. system. The one thing I noticed is that the ECU plug in the harness has five socket while the orange box only has 4 pins.......meaning one of the sockets in the harness has nothing to connect to. In the pics, it is the green wire with red tracer that would connect the missing pin to the ballast resistor.

I would like rule out the differences between the harness and the ECU as being a possible cause of the problem before I move on to other troubleshooting measures. Also, the car has a dual balast.

Thanks for any advice

The first start-up of the day, with the e-choke engaged is ok. After the car heats up, is when the problems start. I have to use the fast idle cam to get it running. If I try to push the throttlle, the engine dies immediately. I haven't been able to set the timing because I can't even see the timing marks. The car has electronic ignition. Now, my aftermarket harness is for an E.I. system. The one thing I noticed is that the ECU plug in the harness has five socket while the orange box only has 4 pins.......meaning one of the sockets in the harness has nothing to connect to. In the pics, it is the green wire with red tracer that would connect the missing pin to the ballast resistor.

I would like rule out the differences between the harness and the ECU as being a possible cause of the problem before I move on to other troubleshooting measures. Also, the car has a dual balast.

Thanks for any advice

.

.