72chally440

Well-Known Member

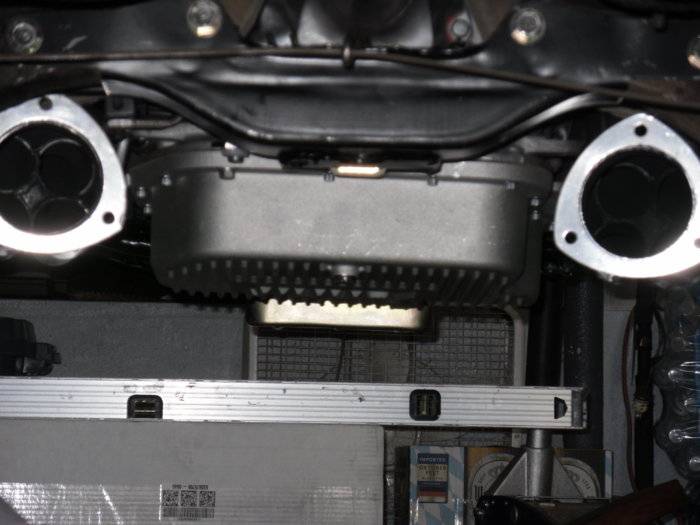

Engine is in now, but I'm having issues getting it to sit level. TTI headers are hitting the floorboard on drivers side. Driver side of engine sitting too high. I found a problem with the Dynatech mity mount pin not inserting fully into k member. Changed mounts to stock style and mounts sit flush now, but driver side is still too high. I replaced trans mount with poly type. I have loosened mounts and lifted engine with hoist and cannot get this engine level. The pics below show engine in bay (Looks Good) and from underneath car showing the driver side header is too high and tight to floorboard. Driver side header to floorboard clearance is about 1/8 inch. Passenger side header to floorboard clearance is correct at about 5/8 inch. The level in front of car shows the oil pan is not level either, so I dont think the header was made wrong. A level across carb shows it off level the same amount. I checked k member and it is level. All preinstall measurements suggested by TTI for proper position of engine on kmember are dead on. Any suggestions on how to lower the drivers side???