I've got a restoration thread going on a few different sites. I've neglected to update this one since I figured most have seen it already. If anyone is still watching this and wants me to post the current pictures let me know.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

origonal owner 73 Rallye

- Thread starter burdar

- Start date

Last fall/winter I was busy refinishing most of the original fasteners. I bead blasted the fasteners that were originally silver zinc and sent them off to be replated.

The fasteners that were originally phosphated(gray in color) were also bead blasted. I purchased some Black Oxide solution from Caswell Plating and experimented with dip times to come up with a color that was close to the factory phosphated finish. I originally also used their Penetrating Sealer once the fasteners were the color I wanted. A few pieces started rusting again this summer with the high humidity so I'm sealing everything again with RPM.(rust preventative magic) It is sold by ECS and should prevent the parts from rusting agian.

I highly recommend the Black Oxide solution for those who want to refinish their fasteners at home. It's easy to do...fast...and the solution doesn't lose its strength quickly. I'm still on my original batch. I accually only mixed up half of the solution and it's still going strong. Don't bother with the Penetrating Sealer. It works as long as you keep a heavy film of it on the part but it also changes the color and stays slightly tacky. If you wipe off the access, the fasteners look nice but will start to rust again in high humidity. Use RPM to seal the fasteners after you color them with the black oxide.

Sorry for this blurry picture but it shows how the fasteners looked before and after they were refinished.

The fasteners that were originally phosphated(gray in color) were also bead blasted. I purchased some Black Oxide solution from Caswell Plating and experimented with dip times to come up with a color that was close to the factory phosphated finish. I originally also used their Penetrating Sealer once the fasteners were the color I wanted. A few pieces started rusting again this summer with the high humidity so I'm sealing everything again with RPM.(rust preventative magic) It is sold by ECS and should prevent the parts from rusting agian.

I highly recommend the Black Oxide solution for those who want to refinish their fasteners at home. It's easy to do...fast...and the solution doesn't lose its strength quickly. I'm still on my original batch. I accually only mixed up half of the solution and it's still going strong. Don't bother with the Penetrating Sealer. It works as long as you keep a heavy film of it on the part but it also changes the color and stays slightly tacky. If you wipe off the access, the fasteners look nice but will start to rust again in high humidity. Use RPM to seal the fasteners after you color them with the black oxide.

Sorry for this blurry picture but it shows how the fasteners looked before and after they were refinished.

Last edited:

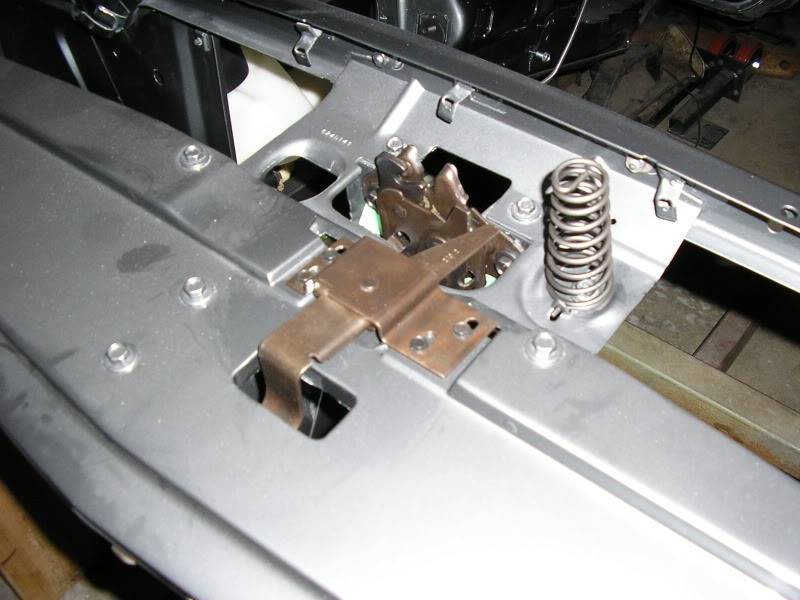

Instead of sending the hood latches out to be refinished, I dipped them in the black oxide solution. The fasteners I'd done turned gray/black and was expecting the latches to do the same thing. They didn't turn gray though. They turned brown. Those parts were originally brown phosphate anyway so it worked out for the best. I have yet to redo these with the RPM but it's on my list. The hood pop-up spring was also dipped in the solution for maybe 10 seconds and turned out nice

Last edited:

I saw some posts on other sites about refinishing the plastic interior pieces so I thought I'd give it a try. I painted the A-pillars and kick panels and they turned out awsome. You can't even tell they are painted. It looks like the original plastic.

I cleaned each part 4 times in preparation for the paint. Once I was happy with how clean they were, I sprayed them with SEM Adhesion Promoter per the instructions on the can. Then I misted the parts with SEM Landau Black.

Here is a refinished A-pillar next to an unfinished one.

Before picture of the kick panels. They had turned gray and were fairly scratched up.

After picture of the kick panels.

These turned out so nice that I'm going to try the same thing on the original door panels and rear interior panels.

I cleaned each part 4 times in preparation for the paint. Once I was happy with how clean they were, I sprayed them with SEM Adhesion Promoter per the instructions on the can. Then I misted the parts with SEM Landau Black.

Here is a refinished A-pillar next to an unfinished one.

Before picture of the kick panels. They had turned gray and were fairly scratched up.

After picture of the kick panels.

These turned out so nice that I'm going to try the same thing on the original door panels and rear interior panels.

This spring, Tim(the guy that did the body and paint) came over to help me with a few things. We trimmed the vinyl top and installed the stainless trim. Previously I bought some buffing wheels and compound and polished up the vinyl top trim and the drip rail trim.

Then we worked on the headliner.

I have a lot of small spring clamps so we put those to good use.

The install when great. I bought the headliner from Dante's Parts. It is made from Yorkshire material just like the original one was. The 73-74 cars didn't use a perforated headliner. The correct material looks like corduroy.

The seat belts look green but that is just due to thte flash. They cleaned up nicely in the washing machine. The sun visors are original and cleaned up good. The rear view mirror was taken apart and cleaned. The base was resprayed with SEM Trim Black.

Then we worked on the headliner.

I have a lot of small spring clamps so we put those to good use.

The install when great. I bought the headliner from Dante's Parts. It is made from Yorkshire material just like the original one was. The 73-74 cars didn't use a perforated headliner. The correct material looks like corduroy.

The seat belts look green but that is just due to thte flash. They cleaned up nicely in the washing machine. The sun visors are original and cleaned up good. The rear view mirror was taken apart and cleaned. The base was resprayed with SEM Trim Black.

I had the front header panel moulding and the front valance moulding stripped and polished but I'm not happy with the way they turned out. I bought a new header panel moulding at the Nat's but the lower valance moulding isn't being repopped right now. Hopefully another run of front valance mouldings will be run sometime.

I cleaned and painted the plastic valance insert with SEM trim black paint. Then I masked off everything but the front lip and painted that with Mopar Rallye wheel paint. It is a close match to the original silver.

The original grill was in decent shape but it was looking old and faded.

I test sprayed some SEM trim black and it was a perfect match to an unfaded section. After cleaning the grill multiple times, I sprayed it with the trim black. The day I sprayed it the humidity was very high. After it had dried it looked awful. It was extremely blotchy. I lightly rubbed the grill down with some 0000 steel wool. That evened out the finish and removed the small amount of orange peel that was visable. You can't tell that the grill is painted now. It looks just like the natural plastic. I masked off everything but the front lip once again and sprayed it with the Rallye wheel paint.

I had three Challenger emblems to choose from. I picked the nicest one and cleaned it up. I took a Q-tip and put it in a jar of petroleum jelly. I used the Q-tip to put a light film of the jelly on the chrome face of the emblem. Then I sprayed the entire thing with the trim black paint. Once the paint was dry, I was able to just wipe off the face of the emblem.

The rubber bumper filler strip was in good shape. It cleaned up and looked new with just a very light wet sanding.

I cleaned and painted the plastic valance insert with SEM trim black paint. Then I masked off everything but the front lip and painted that with Mopar Rallye wheel paint. It is a close match to the original silver.

The original grill was in decent shape but it was looking old and faded.

I test sprayed some SEM trim black and it was a perfect match to an unfaded section. After cleaning the grill multiple times, I sprayed it with the trim black. The day I sprayed it the humidity was very high. After it had dried it looked awful. It was extremely blotchy. I lightly rubbed the grill down with some 0000 steel wool. That evened out the finish and removed the small amount of orange peel that was visable. You can't tell that the grill is painted now. It looks just like the natural plastic. I masked off everything but the front lip once again and sprayed it with the Rallye wheel paint.

I had three Challenger emblems to choose from. I picked the nicest one and cleaned it up. I took a Q-tip and put it in a jar of petroleum jelly. I used the Q-tip to put a light film of the jelly on the chrome face of the emblem. Then I sprayed the entire thing with the trim black paint. Once the paint was dry, I was able to just wipe off the face of the emblem.

The rubber bumper filler strip was in good shape. It cleaned up and looked new with just a very light wet sanding.

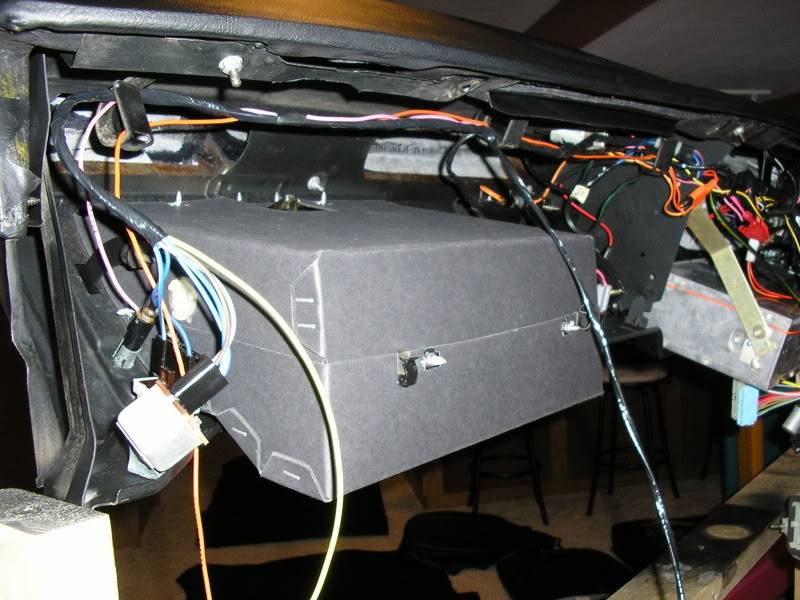

I started tearing into the dash assembly in February. It was a lot of work but it wasn't as difficult as I was thinking it was going to be. I bought all new M&H wiring harnesses just to be on the safe side. Once I got into it, the main dash harness was in good shape except for one connection at the steering column. Still, I feel more comfortable with brand new wiring.

The entire assembly was removed from the car as a unit about 8 years ago. Since that time, the assembly had been sitting upside down on a bench in the garage so it was very dirty.

I took a lot of pictures as well as a few notes so I could get everything back in the proper places. The very last thing that was done was to remove the pad from the frame.

The pad was sent out to Ulitmate Rides but I went through Dave at Roseville Chrysler instead of dealing with UR dirrectly. The gauges were sent off to GCAR for rebuilding.

The entire assembly was removed from the car as a unit about 8 years ago. Since that time, the assembly had been sitting upside down on a bench in the garage so it was very dirty.

I took a lot of pictures as well as a few notes so I could get everything back in the proper places. The very last thing that was done was to remove the pad from the frame.

The pad was sent out to Ulitmate Rides but I went through Dave at Roseville Chrysler instead of dealing with UR dirrectly. The gauges were sent off to GCAR for rebuilding.

After the dash pad and gauges were sent out I started cleaning up the wiring that needed to be reused. The Rallye light bar wiring, along with the "light group" wiring and all the radio/speaker wiring needed to be reused. I removed one secondary harness at a time....cleaned it and installed it on the new harness.

Once the main harness was assembled, I turned my attention to the individual dash components. I cleaned up the headlight/wiper/panel dimmer switches but the map light switch needed more work. It would no longer toggle and had caused a battery drain back when the car was still in service. I sent it to Jim at JS Restorations. He took it completely apart, and rebuilt the switch. He even kept the factory date code on the side of the housing.

The factory plastic MAP LIGHT bezel was broken and I didn't feel like trying to glue it back together. I found an older metal bezel off of a 70 Cuda. I sprayed the bezel with SEM Trim Black paint. Once that was dry, I used some Testors white model paint and painted the recessed letters. It doesn't matter if you get some excess paint on the face of the bezel. Once the white paint has dried for a few hours, just use some mineral spirits on an old T-shirt and remove the excess paint. The SEM paint is uneffected by the mineral sprits.

The heater bezel had seen better days. Some of the factory wrinkle paint was flaking off and the chrome rectangular border was worn in a few places. The white letters on the inside of the bezel no longer looked crisp.

It was a PITA removing the factory wrinkle paint to get down to bare plastic. I tried a few different methods but ended up soaking the bezel in brake fluid. That softened the paint enough so it could be scraped off. Once I was down to bare plastic, I sprayed the center rectangle with SEM trim black paint. I didn't mask anything off...I just sprayed the trim black onto the bezel. Once that was dry, I masked off the rectangular area for the wrinkle paint. Before stripping the factory paint off of the bezel, I sprayed a test of the VHT wrinkle paint since I'd never worked with it before. The test ended up looking just like the factory finish so I went ahead and painted the bezel. You need to do this out in the sun so the wrinkles get tighter. I you don't heat the part, you may not get an even finish.

I let the wrinkle paint dry for 3 weeks. Once I was satisfied that it was dry, I masked off everything except the raised rectangle border around the heater controles. I sprayed that border with two light mist coats of chrome spray paint. It's not as shiny as the factory finish but it looks good. Finally, I used a fine paint pen to repaint the letters on the inside of the bezel. After going over the letter once, they still looked dull and dirty. I had to go over them a second time in order for them to look crisp.

The radio fader knob and bezel are NOS pieces that my dad bought a long time ago.

The bezel around the AM radio was also sprayed with the VHT wrinkle paint. The faceplate of the radio itself was sprayed with SEM trim black and the raised border was sprayed with the chrome paint.

Once the main harness was assembled, I turned my attention to the individual dash components. I cleaned up the headlight/wiper/panel dimmer switches but the map light switch needed more work. It would no longer toggle and had caused a battery drain back when the car was still in service. I sent it to Jim at JS Restorations. He took it completely apart, and rebuilt the switch. He even kept the factory date code on the side of the housing.

The factory plastic MAP LIGHT bezel was broken and I didn't feel like trying to glue it back together. I found an older metal bezel off of a 70 Cuda. I sprayed the bezel with SEM Trim Black paint. Once that was dry, I used some Testors white model paint and painted the recessed letters. It doesn't matter if you get some excess paint on the face of the bezel. Once the white paint has dried for a few hours, just use some mineral spirits on an old T-shirt and remove the excess paint. The SEM paint is uneffected by the mineral sprits.

The heater bezel had seen better days. Some of the factory wrinkle paint was flaking off and the chrome rectangular border was worn in a few places. The white letters on the inside of the bezel no longer looked crisp.

It was a PITA removing the factory wrinkle paint to get down to bare plastic. I tried a few different methods but ended up soaking the bezel in brake fluid. That softened the paint enough so it could be scraped off. Once I was down to bare plastic, I sprayed the center rectangle with SEM trim black paint. I didn't mask anything off...I just sprayed the trim black onto the bezel. Once that was dry, I masked off the rectangular area for the wrinkle paint. Before stripping the factory paint off of the bezel, I sprayed a test of the VHT wrinkle paint since I'd never worked with it before. The test ended up looking just like the factory finish so I went ahead and painted the bezel. You need to do this out in the sun so the wrinkles get tighter. I you don't heat the part, you may not get an even finish.

I let the wrinkle paint dry for 3 weeks. Once I was satisfied that it was dry, I masked off everything except the raised rectangle border around the heater controles. I sprayed that border with two light mist coats of chrome spray paint. It's not as shiny as the factory finish but it looks good. Finally, I used a fine paint pen to repaint the letters on the inside of the bezel. After going over the letter once, they still looked dull and dirty. I had to go over them a second time in order for them to look crisp.

The radio fader knob and bezel are NOS pieces that my dad bought a long time ago.

The bezel around the AM radio was also sprayed with the VHT wrinkle paint. The faceplate of the radio itself was sprayed with SEM trim black and the raised border was sprayed with the chrome paint.

The dash frame was in good shape. After I power washed it, I sprayed a small section with SEM trim black to see how closely it matched the original paint. It accually matched perfectly. I looked at the steering column and some hidden areas of the dash frame for signs of a heavier texture but didn't find any. The SEM paint has a suede look to it so I'm happy with how it turned out.

Once the dash pad and gauges came back, I started putting the dash assembly back together. The woodgrain is new and had to be bent to fit since it's shipped flat. It bent easily using a piece of pipe to push against. It's not quite factory correct but I didn't want to reuse the original faded woodgrain and I didn't want to use a sticker.

Once the dash pad and gauges came back, I started putting the dash assembly back together. The woodgrain is new and had to be bent to fit since it's shipped flat. It bent easily using a piece of pipe to push against. It's not quite factory correct but I didn't want to reuse the original faded woodgrain and I didn't want to use a sticker.

The dash installation went very quickly. The dash was set on the two bolts in the kick panel area. The radio antenna was hooked up and the blower motor wiring was connected. The dash was then rotated up in place and secured with the four small fasteners at the base of the windshield. Once the assembly was in, the heater cables were hooked up and all the other wiring was connected.

Last week the car came down off the body stand. I wasn't able to install the brake and fuel lines with the car on the stand. A guy from work came over with a forklift and lifted the car off the stand.

We put my stands back on the car. The new 6" wheels are a lot nicer then the 4" wheels I had on there before.

We put my stands back on the car. The new 6" wheels are a lot nicer then the 4" wheels I had on there before.

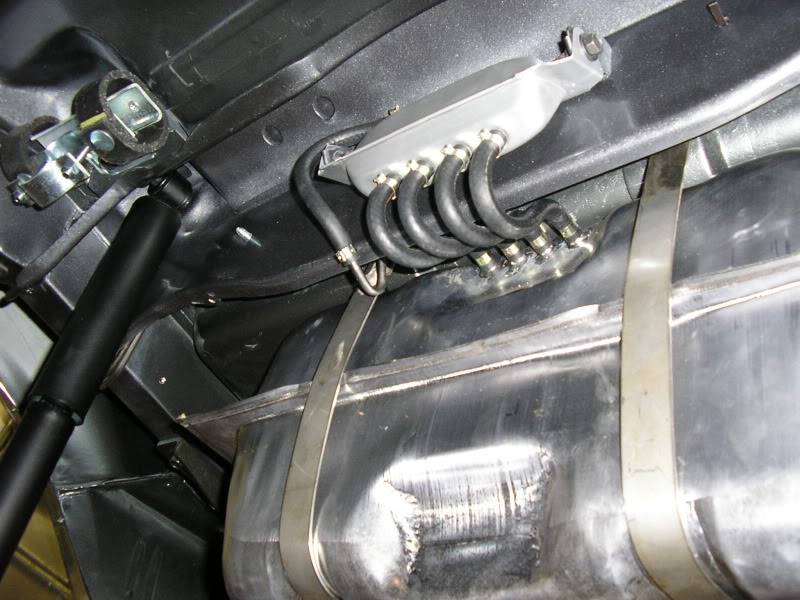

Over the last week, I installed the main brake and fuel lines. I went with stainless lines from Fine Lines. I still had the original lines which I used to make sure the bends were correct. The lines still needed tweeking in a few spots to fit.

Once the lines were on I connected the rear shocks to their upper mounts and installed the passengers side over axle pipe hanger. Before installing the new tank I made a new pad and preassembled the vapor separator onto the tank.

Once the fuel line connection was hooked up I installed the new muffler heat sheilds from Dales Cuda Shop.

Once the lines were on I connected the rear shocks to their upper mounts and installed the passengers side over axle pipe hanger. Before installing the new tank I made a new pad and preassembled the vapor separator onto the tank.

Once the fuel line connection was hooked up I installed the new muffler heat sheilds from Dales Cuda Shop.

Juan Veldez

Well-Known Member

I have the EXACT same car (paint scheme included), except I have the 340. How did you go about adding leaf springs? I was trying to sell mine, but will now finish my restoration too and believe my gals rear is sagging a bit too. Good luck!

Back in the 90's the spring packs were taken apart and a new main leaf(minus the eyes) was bolted under the original main leaf. I taked to a few places that re-arch springs but they basically said it's trial and error getting them at the right height. They also said the springs may sag back down.

I don't have new springs yet but I think I'm going to go with the MP ones. I've heard that ESPO springs are a little better quality but they don't look close to stock. The bad thing is that all new springs are going to come painted. Originaly the springs were left bare metal. I'm going to have to strip the paint off of the new springs which I'm not looking forward to.

I don't have new springs yet but I think I'm going to go with the MP ones. I've heard that ESPO springs are a little better quality but they don't look close to stock. The bad thing is that all new springs are going to come painted. Originaly the springs were left bare metal. I'm going to have to strip the paint off of the new springs which I'm not looking forward to.

WOW. It's been a long time since I've been here. I spend all my time on FABO. LOL

You guys are doing a excellent job! I should stop over sometime and see what you're up to. I just found my old 73 Challenger that I had back in the late 70's I hope I can buy it and restore it to a nice driver. I forgot that Tim painted your car. He is the best! He preps every car like he would paint it black. Flawless! toolmanmike (Mopar Joe's friend)

You guys are doing a excellent job! I should stop over sometime and see what you're up to. I just found my old 73 Challenger that I had back in the late 70's I hope I can buy it and restore it to a nice driver. I forgot that Tim painted your car. He is the best! He preps every car like he would paint it black. Flawless! toolmanmike (Mopar Joe's friend)

Last edited:

Hey Mike...I've been wondering where you went. I made a lot of progress this summer. The plan is to install the rear end, engine and trans in the spring. I'm basically ready for them now but those assemblies need a lot of work before I'll install them.

The rear end is full of pits and the center section is painted with cast blast paint. I just moved the rear end to my place so I can work on it this winter. I'll be filling the pits in the housing and painting it the correct black color. I'll strip the center section and hopefully leave it bare metal.(I'll apply RPM so it doesn't rust.)

I was over at my parents house a couple weeks ago and had a look at the engine. Mice have gotten to it so it will have to come back appart. There are mounds of "Decon" around the exhaust valves. I hope they havn't gotten into the engine.

The suspension will also be stripped of paint and refinished correctly. I painted a lot of parts with POR-15 which was stupid. It's going to take forever to get all that crap off of them.

I'm just about done with the driveshaft. I've got it all sanded down and the welds reheated. I just have to RPM it and install the U-joints.

The rear end is full of pits and the center section is painted with cast blast paint. I just moved the rear end to my place so I can work on it this winter. I'll be filling the pits in the housing and painting it the correct black color. I'll strip the center section and hopefully leave it bare metal.(I'll apply RPM so it doesn't rust.)

I was over at my parents house a couple weeks ago and had a look at the engine. Mice have gotten to it so it will have to come back appart. There are mounds of "Decon" around the exhaust valves. I hope they havn't gotten into the engine.

The suspension will also be stripped of paint and refinished correctly. I painted a lot of parts with POR-15 which was stupid. It's going to take forever to get all that crap off of them.

I'm just about done with the driveshaft. I've got it all sanded down and the welds reheated. I just have to RPM it and install the U-joints.

I don't know whether I can get my old challenger bought or not. I need to call the owner and go take a closer look. I need to get my Dart finished sometime too and don't really have space for another project. (too bad Joe didn't build a bigger shop) LOL But I hate to see it go away. It was such a great car for me. I still have people in town ask me what ever happened to my old "baby blue Challenger" Wish me luck. Mike

a68postcar

Well-Known Member

- Joined

- Feb 5, 2011

- Messages

- 334

- Reaction score

- 8

All I can say is "WOW!!!!!" really nice car dude!

Thanks...so far I think it's coming along pretty good. I'm really getting anxious to drive it. I need to get a lot done this winter in order to have it running by next summer/fall. The fact that the car has to be shoved in the corner of the garage so my wife can put her car inside doesn't help.

A couple weeks ago I was in the garage trying to decide what I wanted to work on next. I saw the driveshaft sitting there so I decided to work on it. Probably seven years ago I wire wheeled the shaft and brushed on some POR-15. Then I sprayed it with Detail Gray spray paint. Since then I've seen some awsome looking driveshafts restored and left bare metal. I wanted to see how nice I could get the driveshaft to look without using any paint. Well, it didn't turn out as nice as I had hoped since it was extremely pitted but I'll show what I ended up with anyway.

I started by brushing on some paint stripper to remove the Detail Gray paint. It came off easily. Here you can see the POR-15 underneith.

Next, I sanded off most of the POR-15 with 80 grit sand paper and removed the U-joints.

I went to the hardware store and bought some 4" PVC pipe and a cap. I poured EvapoRust in the pipe and inserted the driveshaft.

After a day of soaking, the shaft came out rust free. I still had paint and POR-15 on the ends which required a little sandblasting to clean up.

I was shocked to find a nice looking part number still on the driveshaft.

I sanded on the shaft a little but the pits weren't coming out. I got online and found out that driveshafts are only about a 1/16" thick so I decided to just leave it. I lightly bead blasted the shaft to remove some of the sanding marks. Finally, I rubbed it down with steel wool to get rid of the blasted finish. Once the ends were cleaned up I dipped them in my black oxide solution for 30 seconds to darken them. I rubbed them with steel wool to remove some of the darkness on the high spots.

I took the driveshaft to my father-in-laws house and he helped me reapply the heat markings from the end caps being welded to the tube. Over the weekend I heated the driveshaft and applied RPM to it so it won't rust again. I also applied some RPM to the new U-joints. While I had the new joints appart I noticed that one of the caps was missing two of the needles. I returned that one the other day and it is now installed. The only other thing I need to do is have it ballanced.

Here's the finished product. I took this picture without the flash to hide some of the pitting. Hopefully it will look OK under the car.

A couple weeks ago I was in the garage trying to decide what I wanted to work on next. I saw the driveshaft sitting there so I decided to work on it. Probably seven years ago I wire wheeled the shaft and brushed on some POR-15. Then I sprayed it with Detail Gray spray paint. Since then I've seen some awsome looking driveshafts restored and left bare metal. I wanted to see how nice I could get the driveshaft to look without using any paint. Well, it didn't turn out as nice as I had hoped since it was extremely pitted but I'll show what I ended up with anyway.

I started by brushing on some paint stripper to remove the Detail Gray paint. It came off easily. Here you can see the POR-15 underneith.

Next, I sanded off most of the POR-15 with 80 grit sand paper and removed the U-joints.

I went to the hardware store and bought some 4" PVC pipe and a cap. I poured EvapoRust in the pipe and inserted the driveshaft.

After a day of soaking, the shaft came out rust free. I still had paint and POR-15 on the ends which required a little sandblasting to clean up.

I was shocked to find a nice looking part number still on the driveshaft.

I sanded on the shaft a little but the pits weren't coming out. I got online and found out that driveshafts are only about a 1/16" thick so I decided to just leave it. I lightly bead blasted the shaft to remove some of the sanding marks. Finally, I rubbed it down with steel wool to get rid of the blasted finish. Once the ends were cleaned up I dipped them in my black oxide solution for 30 seconds to darken them. I rubbed them with steel wool to remove some of the darkness on the high spots.

I took the driveshaft to my father-in-laws house and he helped me reapply the heat markings from the end caps being welded to the tube. Over the weekend I heated the driveshaft and applied RPM to it so it won't rust again. I also applied some RPM to the new U-joints. While I had the new joints appart I noticed that one of the caps was missing two of the needles. I returned that one the other day and it is now installed. The only other thing I need to do is have it ballanced.

Here's the finished product. I took this picture without the flash to hide some of the pitting. Hopefully it will look OK under the car.

Similar threads

- Replies

- 57

- Views

- 5K

- Replies

- 2

- Views

- 234

- Replies

- 69

- Views

- 7K